V-cut depaneling is an easy way to separate circuit boards from large panels. Manufacturers cut V-shaped grooves along the board edges during production, then simply snap them apart after assembly. This method works great for standard rectangular boards, saving time and money. While it can’t handle special shapes or very thin boards, it’s perfect for most basic PCB manufacturing needs.As a professional with over a decade of experience in the PCB depaneling industry, I will explain the definition, advantages, and disadvantages of V-cut depaneling in this article.

What is PCB V-cut depaneling?

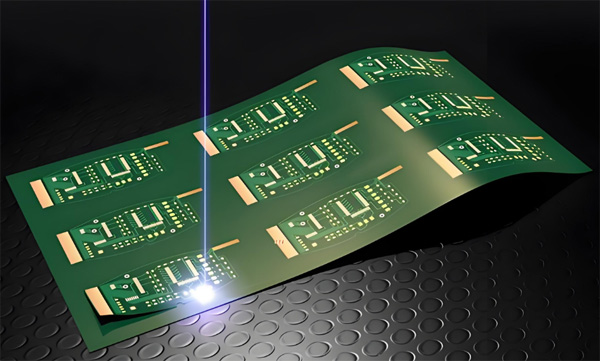

PCB V-cut depaneling is a way to break apart large PCB panels into smaller, individual boards. During manufacturing, V-shaped grooves are cut along the edges where the boards need to separate. After assembly, the panels can be snapped apart by hand or machine, making the process fast and cheap. This method works best for simple, straight cuts and thicker boards, but it can’t handle complex shapes and might stress delicate parts. For more precise or complicated designs, other methods like laser cutting are better. Overall, V-cut is a popular choice because it’s quick and easy.

What are the advantages of using V-cut depaneling for PCBs?

●Low Cost – No expensive cutting tools or lasers are needed; simple scoring and snapping suffice.

●Fast & Efficient – Panels can be separated quickly, either manually or with automated machines, speeding up production.

●Clean Breaks – Produces smooth edges with minimal burrs, reducing the need for extra finishing.

●Good for Thicker Boards – Works well with rigid PCBs (typically >0.8mm thick).

●Simple Process – Easy to implement in manufacturing with no complex programming or tooling.

●Scalable for Mass Production – Ideal for high-volume runs of standard rectangular PCBs.

What are the disadvantages or limitations of V-cut depaneling?

●Only works for straight cuts – Can’t make curved or fancy shapes.

●Can break delicate parts – The snapping force might damage small or fragile components.

●Needs thick boards – Doesn’t work well for thin or flexible circuit boards.

●Edges aren’t perfect – Might leave rough spots or tiny cracks that need cleaning up.

●Wastes some space – The V-grooves take up room on the panel that could be used for more boards.

●Can’t use for all boards – Not good for bendable circuits or very high-quality products.

Seprays’PCB V-cut Depaneling Solutions

ZM30 PCB Round Blade V-CUT Separator

SEPRAYS’ ZM30 Round Knife PCB Separator is suitable for all kinds of PCB circuit boards with V grooves, aluminum substrates, LED circuit boards, LED light strips, etc.

ZM30L PCB Automatic Round Knife Depaneling Machine

The ZM30L PCB Automatic Round Knife Depaneling Machine by SEPRAYS showcases advanced technology tailored for high-precision and damage-free separation of printed circuit boards (PCBs).

Conclusion

For many PCB projects, V-cut separation offers the perfect mix of speed, simplicity and low cost. It’s not the right choice for every situation, but when you’re making standard rectangular boards in large quantities, this method gets the job done quickly and affordably. By choosing V-cut depaneling where appropriate, manufacturers can save money while maintaining good quality results.

A professional with over a decade of experience in the PCB depaneling industry.