PCB delamination is something I’ve often seen cause serious issues in electronics. It happens when the layers inside a printed circuit board start to separate, which can lead to poor performance or even complete failure. In this article, I’ll walk you through what PCB delamination is, why it happens, how to recognize it, and how to prevent it.

- Part 1. What is PCB delamination?

- Part 2. What causes PCB delamination during manufacturing?

- Part 3. How do you detect delamination in a PCB?

- Part 4. What are the signs of PCB delamination?

- Part 5. How does moisture cause PCB delamination?

- Part 6. Can thermal cycling lead to PCB delamination?

- Part 7. How does improper soldering contribute to delamination?

- Part 8. What materials are more prone to PCB delamination?

- Part 9. How to prevent PCB delamination during assembly?

- Part 10. How to repair a delaminated PCB?

- Part 11. FAQs about PCB Delamination

Part 1. What is PCB delamination?

PCB delamination refers to the separation of layers within a printed circuit board. It typically occurs between the copper foil and the dielectric substrate, or between inner laminate layers. This compromises the mechanical strength and electrical performance of the PCB, potentially causing circuit failure, signal loss, or open connections. Delamination is usually the result of thermal, mechanical, or chemical stress during manufacturing, assembly, or operation.

Part 2. What causes PCB delamination during manufacturing?

Delamination during manufacturing can result from improper lamination temperature or pressure, contamination (e.g., dust or oil) between layers, poor material quality, or excessive moisture content in the prepreg or laminate. Incomplete resin curing, excessive drilling heat, or poor plating can also contribute. These issues create weak interfaces that separate under thermal or mechanical stress during later stages.

Part 3. How do you detect delamination in a PCB?

Delamination can be detected using visual inspection (bubbles, warping), X-ray imaging, ultrasonic scanning, or thermal analysis methods. In some cases, electrical testing (like continuity or impedance checks) may reveal faults caused by layer separation. Advanced detection tools like time-domain reflectometry (TDR) or cross-sectioning are also used to identify internal defects.

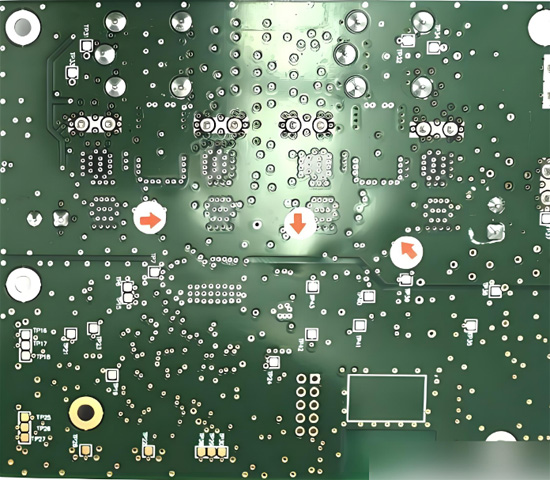

Part 4. What are the signs of PCB delamination?

Signs include visible bubbles, bulging areas, or wrinkles between layers, unusual smells during rework, cracking sounds under thermal stress, or discoloration. Functionally, it may lead to intermittent or open circuits, increased impedance, or poor signal transmission. These symptoms may become more obvious during thermal cycles or soldering.

Part 5. How does moisture cause PCB delamination?

Moisture trapped in the PCB material expands rapidly when exposed to heat during soldering or reflow processes. This can create internal pressure that forces the layers apart, resulting in delamination. High humidity during storage or insufficient pre-bake of materials are common causes. Moisture also degrades adhesive properties between layers over time.

Part 6. Can thermal cycling lead to PCB delamination?

Yes. Repeated heating and cooling cycles cause materials in the PCB to expand and contract. Since different layers (e.g., copper and dielectric) have different thermal expansion coefficients, this mismatch stresses the interfaces. Over time, this stress can break down the adhesive bonds and cause layer separation, especially in poorly manufactured boards.

Part 7. How does improper soldering contribute to delamination?

Improper soldering—such as excessive heat, prolonged soldering times, or uneven heating—can overheat the board, breaking down the adhesive bonds between layers. Using a soldering iron with incorrect temperature settings or poor thermal profiling in reflow ovens increases the risk. Repeated rework or hot air exposure can also trigger delamination.

Part 8. What materials are more prone to PCB delamination?

Low-grade FR4 materials, improperly cured resins, or high-CTE (coefficient of thermal expansion) substrates are more susceptible. Materials with poor moisture resistance or weak adhesive bonding between layers are also at risk. In general, cheaper or low-Tg (glass transition temperature) laminates tend to delaminate more easily under heat or stress.

Part 9. How to prevent PCB delamination during assembly?

Prevention includes using high-quality materials, properly drying boards (pre-baking) before soldering, and following correct thermal profiles during reflow or wave soldering. Avoid excessive drilling heat, contamination, and rough handling. Design guidelines like proper via placement and spacing can also reduce stress on critical areas.

Part 10. How to repair a delaminated PCB?

Repairing delamination is difficult and often not recommended for multilayer PCBs. Minor delamination near corners or non-critical areas may be fixed using epoxy injection and clamping. However, this is temporary and not always reliable. In most cases, the best option is to scrap the defective board and address the root cause to prevent recurrence.

Part 11. FAQs about PCB Delamination

What testing methods are used for PCB delamination?

Common methods include visual inspection, X-ray, ultrasonic scanning, cross-sectioning, and thermal stress testing to detect internal layer separation.

Can PCB delamination affect electrical performance?

Yes, delamination can cause open circuits, impedance issues, and signal loss, reducing reliability and performance of the PCB.

What standards address PCB delamination (e.g., IPC-A-600)?

IPC-A-600, IPC-6012, and IPC-TM-650 outline inspection criteria and test methods for identifying and preventing delamination.

How does delamination impact multilayer PCBs?

Delamination can break internal connections, cause short circuits, and compromise structural integrity in multilayer boards.

Can delamination occur in flexible PCBs?

Yes, though less common, poor bonding or thermal stress can still cause delamination in flexible PCBs.

How does excessive heat during reflow cause delamination?

High temperatures can vaporize trapped moisture or degrade resin, leading to internal pressure and layer separation.

What are common process errors leading to PCB delamination?

Errors include poor lamination, contamination, insufficient drying, improper drilling, and incorrect thermal profiles.

How do you handle delamination in high-frequency PCBs?

Use high-Tg, low-loss materials, strict process control, and ensure clean lamination to avoid signal disruption.

Is PCB delamination reversible?

No, most delamination is permanent. Minor damage may be patched, but full electrical integrity is rarely restored.

What is the difference between blistering and delamination in PCBs?

Blistering is localized bubbling of layers; delamination is broader separation between layers across the PCB structure.

A professional with over a decade of experience in the PCB depaneling industry.