When it comes to laser depaneling, many people’s first reaction is often that it’s too expensive, leading them to dismiss learning about it altogether—a decision that could result in significant missed opportunities. As a professional with over a decade of experience in the PCB depaneling industry, I will address some frequently asked questions about laser depaneling in this article.

- Part1. What is laser depaneling in PCB manufacturing?

- Part2. How does laser depaneling work?

- Part3. What types of lasers are used for PCB depaneling?

- Part4. What are the benefits of laser depaneling compared to mechanical methods?

- Part5. Is laser depaneling suitable for all types of PCBs?

- Part6. Can laser depaneling be used on flexible PCBs?

- Part7. What materials can be cut using laser depaneling?

- Part8. What are the limitations of laser depaneling?

- Part9. Does laser depaneling cause thermal damage to PCBs?

- Part10. What industries commonly use laser depaneling?

- Part 11. FAQs about laser depaneling

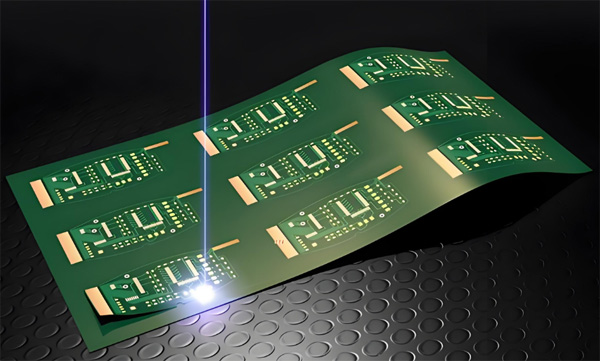

Part1. What is laser depaneling in PCB manufacturing?

Laser depaneling is a non-contact method used to separate individual printed circuit boards (PCBs) from a larger panel after assembly. Unlike mechanical methods like routing or punching, laser depaneling uses a focused laser beam to precisely cut through the substrate, solder mask, and thin copper layers without physical force. This technique is ideal for high-density, delicate, or complex PCB designs where mechanical stress could damage components or traces. It offers high precision, clean edges, and minimal material waste, making it suitable for advanced electronics manufacturing.

Part2. How does laser depaneling work?

Laser depaneling works by directing a high-energy laser beam onto the PCB panel along predefined cutting paths (typically defined in CAD files). The laser vaporizes or ablates the material along these paths, creating smooth, burr-free edges. The process is computer-controlled, ensuring accuracy and repeatability. Different laser types (UV, CO₂, or fiber) are chosen based on material properties. Since it’s a non-contact method, there’s no mechanical stress, reducing the risk of microcracks or component damage. Some systems use vision alignment to ensure precise cuts even if panel placement varies slightly.

Part3. What types of lasers are used for PCB depaneling?

●UV Lasers (355 nm): Best for fine-feature cutting, flexible PCBs, and sensitive materials; minimal heat-affected zone (HAZ).

●CO₂ Lasers (9.3–10.6 µm): Effective for organic materials like FR4 but less precise for metal layers; often used for thicker PCBs.

●Fiber Lasers (1 µm): Good for metals but can generate more heat; less common for depaneling unless hybrid materials are involved.

UV lasers are most popular due to their precision and minimal thermal impact.

Part4. What are the benefits of laser depaneling compared to mechanical methods?

●No Mechanical Stress: Eliminates risk of cracks or delamination.

●Higher Precision: Enables complex, tight-tolerance cuts (e.g., for ultra-thin traces).

●Cleaner Edges: No burrs or debris, reducing post-processing.

●Flexibility: Easily adapts to design changes via software.

●No Tool Wear: Unlike blades or routers, lasers don’t degrade.

●Faster for Small Batches: No need for custom fixtures.

Part5. Is laser depaneling suitable for all types of PCBs?

No—it depends on materials and design. Laser depaneling excels with:

●High-density interconnect (HDI) PCBs.

●Rigid-flex or flexible PCBs.

●Boards with sensitive components.

However, it’s less ideal for:

●Thick metal-core PCBs (e.g., aluminum substrates).

●Panels with heavy copper layers (>3 oz), which may reflect/absorb laser energy unevenly.

Part6. Can laser depaneling be used on flexible PCBs?

Yes, it’s ideal for flexible PCBs (e.g., polyimide films). UV lasers provide clean, precise cuts without mechanical stress that could damage thin, bendable layers. The non-contact process avoids delamination or tearing, common issues with blade-based methods.

Part7. What materials can be cut using laser depaneling?

●Substrates: FR4, polyimide, Rogers materials.

●Conductive Layers: Thin copper (up to ~3 oz).

●Solder Masks & Coatings.

●Adhesives & Coverlays (in flex PCBs).

Metals like aluminum or thick copper may require alternative methods.

Part8. What are the limitations of laser depaneling?

●Thermal Sensitivity: Some heat buildup can affect nearby components.

●Material Restrictions: Struggles with highly reflective/thick metals.

●Cost: Higher initial investment than mechanical methods.

●Speed: Slower for very large panels vs. mass-production routing.

Part9. Does laser depaneling cause thermal damage to PCBs?

Minimal if properly controlled. UV lasers, especially, have a small heat-affected zone (HAZ). However, excessive power or slow cutting can cause localized heating. Proper parameter tuning (pulse duration, wavelength) mitigates this risk.

Part10. What industries commonly use laser depaneling?

●Consumer Electronics: Smartphones, wearables.

●Medical Devices: Implants, diagnostic equipment.

●Automotive: ADAS, infotainment systems.

●Aerospace/Military: High-reliability PCBs.

●IoT & Telecom: Miniaturized, high-density designs.

Part 11. FAQs about laser depaneling

1.Is laser depaneling suitable for high-volume production?

Yes, but with limitations. It’s ideal for high-mix, low-to-medium volumes due to slower speeds than mechanical methods. Automation can improve throughput.

2.How accurate is laser depaneling?

Extremely precise—typical accuracy is ±25–50 µm, with UV lasers achieving even finer cuts (<20 µm), ideal for high-density PCBs.

3.How fast is the laser depaneling process?

Slower than routing (e.g., 100–300 mm/s), but speed varies by material and laser type. UV lasers are slower but more precise.

4.Can laser depaneling be automated?

Yes—automated systems with vision alignment and conveyor integration enable unmanned operation, boosting efficiency for batch processing.

5.What is the typical cost of a laser depaneling system?

$50,000–$300,000+, depending on laser type (UV lasers are pricier) and features like automation or multi-axis cutting.

6.What safety measures are needed for laser depaneling machines?

Enclosed systems, interlocks, laser safety goggles, and proper ventilation to manage fumes. Compliance with Class 4 laser standards is essential.

7.How does laser depaneling affect edge quality?

Produces clean, burr-free edges with minimal debris—superior to mechanical methods. No post-processing is needed for most applications.

8.Can laser depaneling replace V-Cut or routing?

Partially—it’s better for delicate or complex designs but struggles with thick panels or high-volume production where V-cut/routing excel.

9.How much maintenance does a laser depaneling machine require?

Low maintenance—no physical blades to replace. Regular lens cleaning, coolant checks (for some lasers), and calibration are primary needs.

10.What is the typical lifespan of a laser depaneling machine?

10+ years with proper care. Laser sources (e.g., UV diodes) may need replacement after 20,000–30,000 hours of use.

A professional with over a decade of experience in the PCB depaneling industry.