As someone deeply involved in PCB manufacturing, I’ve worked with various depaneling methods over the years. Among them, router depaneling stands out as a reliable and cost-effective technique for separating circuit boards from their panels. While it may not be as high-tech as laser cutting, I’ve found it to be a practical solution—especially when dealing with standard rigid PCBs or complex shapes. Let me walk you through what I’ve learned about the router depaneling process, its effects on quality, and when it’s the right (or wrong) tool for the job.

- Part 1. What is the typical process flow for router depaneling?

- Part 2. How does router depaneling impact PCB quality and reliability?

- Part 3. How does router depaneling affect the mechanical stress on PCBs?

- Part 4. What types of PCBs are best suited for router depaneling?

- Part 5. What types of PCBs are not suitable for router depaneling?

- Conclusion

Part 1. What is the typical process flow for router depaneling?

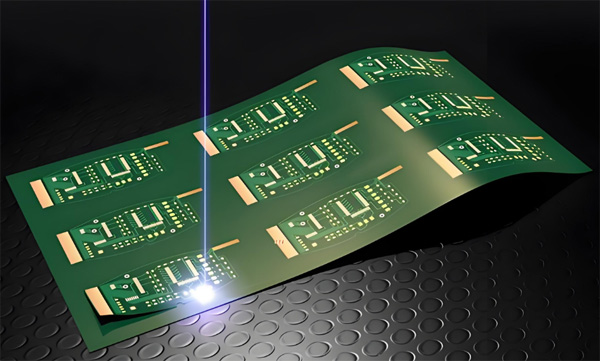

Router depaneling is a mechanical process used to separate individual PCBs from a larger panel using a high-speed rotating bit. The process begins with preparing the panel, which typically includes pre-routed slots or tabs and fiducial marks for alignment. The panel is then loaded into a PCB router machine, where it is securely held in place using clamps or vacuum suction. Optical systems align the panel based on the fiducials to ensure precise cutting. The router follows a pre-programmed path, cutting along the designated areas to separate the boards. Throughout the process, a dust collection system removes debris to keep the workspace clean and prevent contamination. Once the boards are cut, they are collected manually or by a robot and inspected for quality. Although router depaneling is less precise than laser cutting, it is a fast, cost-effective method widely used for thicker or more robust PCBs.

Part 2. How does router depaneling impact PCB quality and reliability?

Router depaneling can affect the quality and reliability of PCBs in both positive and negative ways. On the positive side, it applies relatively low mechanical stress during cutting, which helps protect delicate components and reduces the risk of cracks or damage. It also offers consistent results when properly programmed, making it suitable for medium to high-volume production. However, router depaneling can produce dust and small debris, which may affect board cleanliness if not properly managed. Over time, the router bits can wear down, leading to rougher edges or less precise cuts. Additionally, slight heat generation during cutting can impact sensitive materials. Overall, router depaneling is a reliable method for many types of PCBs, especially when proper tools, maintenance, and dust control systems are in place.

Part 3. How does router depaneling affect the mechanical stress on PCBs?

Router depaneling generally applies moderate mechanical stress to PCBs, but much less than traditional methods like manual breaking or using a V-groove cutter. The router uses a spinning bit to mill along the board’s edges, which helps reduce bending or twisting during separation. This makes it safer for components placed near the edges of the board. However, some mechanical vibration still occurs, and if not carefully controlled, it can lead to microcracks or weakened solder joints. To minimize stress, proper fixturing and bit selection are important. When done correctly, router depaneling offers a good balance between speed, precision, and mechanical safety.

Part 4. What types of PCBs are best suited for router depaneling?

●Rigid PCBs (e.g., FR4):

Ideal for router depaneling due to their strength and durability. They can handle the mechanical forces without cracking or bending.

●Rigid-Flex PCBs:

Suitable when routing is used on the rigid sections only. The flexible parts are left untouched to avoid damage.

●Boards with Complex Shapes:

Routers can follow precise paths, making them great for PCBs with irregular outlines or cutouts.

●Boards with Edge Components:

Routing is accurate enough to cut closely around parts located near the edges without causing harm.

Part 5. What types of PCBs are not suitable for router depaneling?

●Flexible PCBs (FPCs):

These thin and bendable boards are too delicate for mechanical routing. The physical stress can tear or distort them.

●Very Thin Rigid PCBs:

Boards with low thickness may crack, chip, or warp under the pressure of the router bit.

●Boards with Sensitive Edge Components:

If components are placed too close to the edge, they may be damaged by vibrations or contact during the routing process.

●High-Density PCBs with Tight Panel Spacing:

Router bits require space to move. If PCBs are packed too closely, there’s not enough room for safe routing without damaging adjacent boards.

●Ceramic or Brittle Substrates:

These materials can crack easily with mechanical force, making laser or other non-contact methods a better choice.

Conclusion

Reflecting on my experiences, router depaneling remains a trusted workhorse in PCB production, offering speed and versatility for the right types of boards. Yet, it demands careful handling—whether in tool maintenance, dust control, or selecting compatible designs. While it’s not perfect for every scenario (like delicate flex PCBs or ultra-thin substrates), its advantages in precision and stress reduction make it indispensable for many projects. As technology evolves, so do depaneling methods, but for now, mastering the router’s nuances is a skill I rely on to deliver reliable, high-quality PCBs.

A professional with over a decade of experience in the PCB depaneling industry.