Features

1. Multi-Stage Cutting Technology

Utilizes three distinct cutting units (A, B, and C) that operate in sequential stages, allowing for refined, controlled cuts that ensure smoother surfaces and reduced risk of board damage.

2. Reduced Cutting Stress

The multi-stage cutting process lowers cutting stress by more than 80%, significantly minimizing the chance of PCB deformation, which is critical for maintaining board functionality and appearance.

3. Superior Edge Finish

Ensures flat, burr-free board edges and prevents surface warping or twisting, meeting the high precision requirements of advanced circuit board applications.

4. High Production Efficiency

Designed for walkaway operation with minimal manual intervention, making it ideal for improving throughput and consistency in high-volume, high-value PCBA production lines.

5. Ideal for Sensitive Electronics

Particularly suited for depaneling sensitive or high-specification PCBs used in industries where reliability and durability are essential, such as medical, aerospace, or automotive electronics.

Look no further! The same machines used by world’s top 500companies

Send us a direct message now, justsend us a picture of your product andwe’ll be able to recommend the rightproduct for you right away.

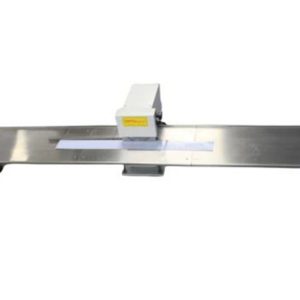

Specifications

| Model | ZM30-L |

| Cutting length | Unlimited length |

| Thickness | 0.5~3mm |

| Circuit board type | Aluminum substrate, Copper substrate, FR1~4, Glass fiber plate |

| Feeding speed | 0~400mm/s |

| Machine size (mm) | 325*380*333 |

| Inlet/outlet tray table size (mm) | 1200*506*333 / 2400*506*333 |

| Blade type | SKH high speed steel |

| Weight | 33 kg + 6kg(1200mm) +15kg(2400mm) |

| Power | 230V/50HZ,110V/60W |

| Hourly workload | 800 |