Features

●Compact and Efficient Design

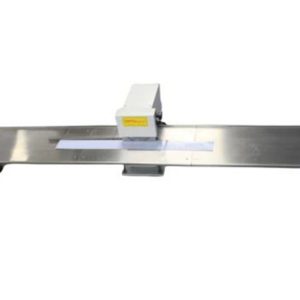

High-performance depaneling machine with a small footprint and high precision, designed for maximum productivity in limited space.

●Single Table with Continuous Operation

Equipped with a single working table that supports uninterrupted processing to enhance production efficiency. Includes a safety grating for operator protection.

●Automated Vision Alignment System

Automatically detects fiducial marks for precise alignment. Includes real-time track position display and allows setting of production output statistics and other parameters.

●Advanced Dust Control System

Uses negative pressure dust removal with secondary dust filtration and an anti-static system to completely eliminate cutting dust and maintain a clean work environment.

●Versatile Application Range

Ideal for depaneling multi-connected PCBs used in consumer electronics, household electronics, automotive electronics, and similar industries.

Look no further! The same machines used by world’s top 500companies

Send us a direct message now, justsend us a picture of your product andwe’ll be able to recommend the rightproduct for you right away.

Specifications

| Model | ZM30-V |

|---|---|

| Working area (substrate machinable size min-max) | X:300mm,Y:350mm,Z: 0-80mm (Min50*50mm,Max300*300MM) |

| Equipment size | L850mm*W850mm*H1520mm |

| Saw blade spindle speed | 8000rpm(optional) |

| X、Y、Z axis driving speed | X,Y axis speed 5-500mm/s, Z axis speed 5-80mm/s, X,Y,Z axis minimum moving distance is 0.01MM |

| Cutting PCB thickness range | 0.2-3mm (saw blade thickness is only 0.2mm) |

| Cutting accuracy, ability | ± 0.05mm Ability to cut straight line, arc, circle, L-type, U-type, stamp hole models, V slot models |

| Machine power (including dust collector) | 5000W |

| Tool change mode | manual tool change (need special tool wrench to change) |

| Table Quantity, function | SingleTable |

| Spindle cooling system | Air cooling method |

| Dust collector power and mode | 3.5kw 380V three-phase motor, external upper/lower dust collector (optional) |

| Air pressure | above 0.45Mpa |

| Working power supply | 220V, 50HZ(dust collector:380V,50HZ) |

| Safety device | adopting safety guard door or sensor |

| Model mode | off-line model, manual loading and unloading |

| Fixtures | universal fixtures are available |

| Automatic fault detection and maintenance mode | the system has a self-diagnostic function, real-time error message display, can intuitively query the status of the device’s various IO ports, easy to troubleshooting |

| Technical support and training | to provide equipment operation, programming, hardware maintenance, maintenance training services; program permanent free upgrade. (Required) |

| Substrate thickness | 0.3-3.5mm |

| Vision system | CCD vision positioning correction system |

| Weight | Approx 600kg |

| Adjustable height of foot | 50~70mm |

| Working range protection | adopting six-face door blind protection method |

| Door interlock protection sensor | safety door microswitch sensor |

| Emergency stop button | yes |

| Circular knife & milling knife method | saw tooth thickness 0.2mm~0.3mm (effectively improve cutting accuracy) (optional) |