Features

●The V-groove separator has further improved the quality of PCB separating.

●Fully automatic operation from loading, cutting, discharging and waste collection.

●It can realize the automatic separating of V- groove X and Y directions.

●Can be flat without burr after cutting. Including aluminum/copper boards, FR4, and glass fiber boards.

●When lines changing, replace the blade mold and suction cup part, and adjust the blade without manually to save time.

●According to customer needs, PCB boards can be automatically placed into the tray or transported away by the assembly line.

Look no further! The same machines used by the world’s top 500companies

More than one thousand well-known enterprises chose Seprays separator and established long-term cooperation.

Send us a direct message now, just send us a picture of your product and we’ll be able to recommend the right product for you immediately.

Product Parameters

| Model | ZM30-ASV |

|---|---|

| Valid cutting size | 350*350mm |

| Table size | 370*400mm |

| Working height | 900±20mm |

| Cutting precision | ±0.1mm |

| Repeat precision | ±0.02mm |

| Cutting speed | 100mm/s |

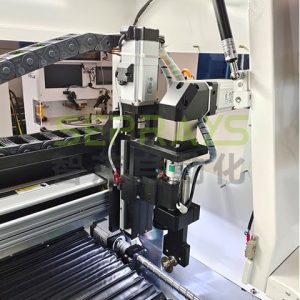

| Architecture | The feeding is rail feeding, manipulator for loading and unloading, circular cutter head/ V cutting head with adjustable height horizontally. |

| Feeding method | The track enters the board, and the PCB directly flows into the |

| Discharging method | Module output/ belt line output/ track output |

| Transfer method | Manipulator handling, vacuum suctio |

| Movement direction | Left to right or right to left |

| Max moving speed | 1000mm/s |

| Max moving trip | Manipulator X-axis 1: 610mm Sub-board X-axis: 530mm Sub-board Y-axis: 600mm |

| Operation interface | WIN10 Windows operation interface |

| Program teaching method | Manual teaching/ CAD import |

| Program backup | USB data transfer |

| Working area | 4.5~6kgf/cm² |

| Voltage/Power requirement | AC:220±10% 50/60Hz 2.5KW |

| Dimensions(W*D*H) | 1180*1246*1684mm |

| Weight | 1000kg |