Features

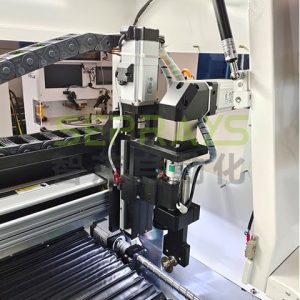

- Full Automation: This machine automates the entire process from PCB loading to cutting and unloading, significantly reducing the need for manual handling and thereby increasing production efficiency and throughput.

- Precision Positioning Technology: Equipped with advanced positioning systems, it guarantees accurate cuts that protect the integrity of the PCBA, preventing damage to components and traces. This feature is vital for maintaining high product quality standards.

- Flexible Material Handling: Its design incorporates suction cups and belt conveyors that are adaptable to varying sizes and shapes of PCBAs, ensuring compatibility with a wide range of board designs without sacrificing efficiency or accuracy.

- Integrated Waste Management: The system instantly collects and manages debris generated during the depaneling process, keeping the workspace clean and organized. This not only optimizes the production workflow but also contributes to a safer and more pleasant working environment.

- Continuous Cycle Operation: Built for continuous operation, the ZM30-LT is perfectly suited for mass production lines where downtime must be minimized. Its capability to run uninterrupted supports high-volume manufacturing demands.

Look no further! The same machines used by world’s top 500companies

Send us a direct message now, justsend us a picture of your product andwe’ll be able to recommend the rightproduct for you right away.

Specifications

| Model | ZM30-LT |

| Equipment size | L:1250 MM、W:615 MM、H:1055 MM |

| Equipment voltage | 220V |

| Air source | 0.4-0.6 Mpa |

| Split distance | Must be greater than 8 MM |

| Max width | 150-300 MM(can be customized widera) |

| Production speed | 300 PCS/H |

| Thinkness | 0.2-3.5 MM |

| Adjustable range of knife axis | 5MM(up and down adjustable) |