Features

- Product Compatibility: Handles PCBAs with a width range of 75mm to 300mm, ensuring flexibility in processing various panel sizes.

- Quick Blade Change: Easy adjustments for different product widths and spacings, minimizing downtime and maximizing production efficiency.

- User-Friendly Interface: Simplified HMI for enabling or disabling functions, reducing the learning curve and making it easy for operators to use.

- Safety Features: Light curtains and acrylic cover provide a safe working environment for operators.

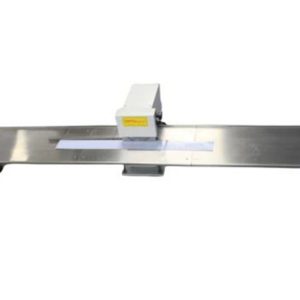

- Compact Design: Dimensions: 1100mm (L) x 480mm (W) x 678mm (H), suitable for installation in designated cleanroom spaces.

- High Production Rate: Capable of achieving a production rate of approximately 200 pieces per hour, depending on the product.

- Cutting Precision: Adjustable knife distance for thicknesses ranging from 0.2mm to 3.5mm, with a precision gap adjustment of 0.01mm.

Look no further! The same machines used by world’s top 500companies

Send us a direct message now, justsend us a picture of your product andwe’ll be able to recommend the rightproduct for you right away.

Specifications

| Feature / Specification | Description |

| Product Compatibility | Minimum product width: 75mm – Maximum product width: 300mm |

| Blade dies Changeover | Quick changeover based on product width and spacing |

| Human-Machine Interface (HMI) | Electrical controls for easy activation and deactivation of functions |

| Safety Features | Light curtains and acrylic cover for operator safety |

| Structure and Design | Floor-standing structure – Steel frame with sheet metal enclosure and powder coating |

| Material Handling | Worktable made of 45 # steel, A3 steel, or national standard aluminum, with rust-resistant electroplating |

| Dimensions | Length: 1100mm / Width: 480mm / Height: 678mm |

| Working Environment | Cleanroom use – Temperature: 0°C to 40°C / Humidity: 10% to 80% – Noise level: 40dB to 80dB – Vibration speed: 1mm/s to 5mm/s |

| Stability and Mobility | Anti-slip and vibration-reducing footpads |

| Networking and Communication | SMEMA interface for equipment integration – Network connectivity for future expansion |

| Power and Air Supply | Power supply: AC 220V / Air pressure: 4-6 KGF/cm² |

| Safety and Operation | Necessary safety devices and operational stability elements |

| Production Capacity | Approximate capacity: 200 PCS/H (dependent on product) |

| Data Monitoring | Monitoring of uptime, production output, faults, and automatic rejection system |

| Cutting Mechanism | Upper rotating knife and lower straight knife |

| Cutting Precision | Adjustable knife distance for thickness: 0.2mm to 3.5mm<br>- Knife gap adjustment precision: 0.01mm |

| Control System | Precise cutting based on set parameters |

| Materials Supported | Aluminum base plate, copper base plate, FR4, fiberglass board |

| Conveyor Belt Speed | Adjustable speed for feeding and post-processing conveyors |

| Feed Mechanism Adjustment | Adjustable based on product width |

| Drive System | Stepper motor for initial and automatic spacing feeding |

| Precision Components | C7 grade ball screw for 0.02mm precision / Medium-load linear guide rails / 3M synchronous pulley for connections |

| Installation and Maintenance | Key components with positioning pins for easy replacement and maintenance |