Features

-

Safe and Efficient for Post-Insertion PCBA Separation:

Especially suitable for separating PCBA boards after component insertion, ensuring the protection of electronic parts and improving downstream process efficiency. -

Optional Automation Module Available:

Offers an optional automation module that includes automatic feeding, slitting, and board receiving functions—making operation faster, easier, and more efficient. -

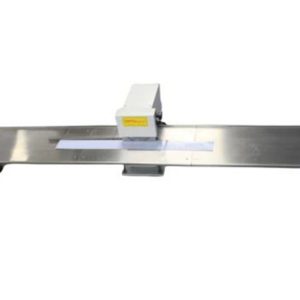

Accurate Dual-Knife Cutting Process:

Features precise parameter settings and an efficient dual-knife cutting mechanism for high-accuracy depaneling. -

High-Speed Multi-Blade Slitting:

Supports multiple tool heads and slitting groups for fast, accurate, and high-throughput board separation. -

Automatic Output with Seamless Integration:

Provides automatic board output and docking, enabling seamless connection to subsequent production processes and enhancing overall production flow.

Look no further! The same machines used by world’s top 500companies

Send us a direct message now, justsend us a picture of your product andwe’ll be able to recommend the rightproduct for you right away.

Specifications

| Model | ZM30-A |

|---|---|

| Size | 1500*800*1500mm |

| Shape | Vertical |

| Weight | 300KG |

| Color | computer white |

| Power supply | AC220V 1000W |

| Environmental requirements | clean and dry environment, avoid humidity or high temperature |

| Working air pressure/tube diameter | >0.6MP/8mm |

| Minimum cutting distance | ≥1.5mm |

| Splitting width | 300mm*300mm / 12*12mm |

| Board inlet adjustment | front side fixed, rear side movable adjustment |

| Maximum height of PCB components | 20mm for PCB reverse side parts, 35mm for front side parts |

| Parameter setting | according to the size of the V-slot touch screen direct input |

| Storage module | can store 50 groups of programs |

| Blade | Japan imported high-speed steel knife |

| Blade angle | 10-30 degrees (selectable) |

| Die precision | 0.1mm |

| Partitioning efficiency | 15s/pcs(200*150mm) standard speed cut 8 knives for reference |

| Maximum length and width of assembly line | 650mm*250mm |

| Split board speed | 0-800mm/s |

| Suction cup manipulator control mode | stepping motor + guide rail + belt drive |

| Dust suction mode and power | 1500W under the knife group dust suction |

| Board thickness | 0.4-3.5mm |

| Misoperation protection | triple protection of grating, sensor and software. |

| Safety protection | emergency stop |

| Power failure and air cut-off function | Yes |

| Self-test function | power-on time monitoring, capacity monitoring, equipment failure information and automatic elimination system |

| The main parts of the machine | board feeder (assembly line), suction cups, three-axis mobile slitting flat, vacuum cleaner |

| Work mode | automatic robot on-line slitting and feeding boards |

| Suitable for | Insertion / SMD / Dual Direction |