Features

- Efficiency: High production capacity of over 100,000 pieces per day, significantly reducing labor costs.

- Automation: Can be connected to feeding equipment for fully automated production.

- User-Friendly: Easy to operate after a simple training session; operators can quickly learn how to adjust the knives.

- Mobility and Stability: Equipped with adjustable height foot cups and wheels for easy movement and stable positioning; foot cup adjustment range is over 50mm.

- Power Requirements: Operates on AC220V power supply and requires a compressed air source of 4-6KGF/cm².

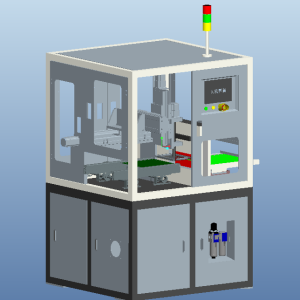

- Safety: Transparent cover and knife housing provide dual protection to ensure operator safety.

- Precision: Knife spacing can be precisely adjusted to ±0.1mm, suitable for PCBs with a thickness range of 0.6 to 3.5mm.

- Cutting Capability: 8mm-wide knives can cut LED light strip boards of 8mm or more in width (boards narrower than 8mm can be customized).

- Cut Quality: Equipped with 40 knives for sequential cutting, ensuring no deformation or bending of the PCB post-cutting.

Look no further! The same machines used by world’s top 500companies

Send us a direct message now, justsend us a picture of your product andwe’ll be able to recommend the rightproduct for you right away.

Specifications

| Machine Model | ZM-30D B / ZM-30D A / ZM-30D |

| Machine Size | 2560*685*1160 / 2690*685*1160 / 1900*685*1160 |

| Shear Length | 100mm-unlimited |

| Shear Width | 8-230MM |

| Shear Speed | 0-300mm/s adjustable |

| V-slot thickness | 0.2-3MM |

| Component Height | ≦12.5mm |

| Distance between component and V-slot | ≧3mm |

| Voltage | 220V/50Hz(110V/60Hz) |

| Pressure(dry air source) | 0.50-0.70Mpa |

| Power | 800W |

| Blade dimension | 80*35*8mm(SKH-11high speed steel imported, by Taiwan process, repeated usage after polish) |

| Blades Qty Configured | 40PCS / 20PCS |

| PCB Compatible | T5、T8 LED strip / Lamp Plate |