Features

●Easy Production Switching

Easily switch between different production types by installing interchangeable tools.

●3-Step Inline Feeding System

Features a simplified 3-step track-based feeding system for efficient and smooth material handling.

●User-Friendly Operation

Conductive and intuitive operation allows workers to learn and operate the system quickly.

●Standardized, Safe, and Reliable System

The equipment is designed with a standardized interface, ensuring operational safety and system reliability.

●MES System Integration

Fully compatible with MES (Manufacturing Execution System) for seamless digital integration.

●Enclosed Working Area for Safety

The entire working area is enclosed to enhance safety during processing and operation.

Optional

- UV laser 15w, 20w, 25w or Green laser 35w, 60w

- Laser Height Sensor

- Barcode reader and MES system integration

- Laser cam power detection

Specifications

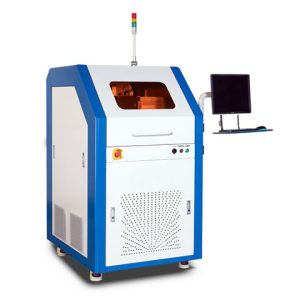

| Model | ZAM340 |

|---|---|

| Vaild cutting size | 350*350mm |

| Cutting function | Tweening to staight line,L shape,U shape,Circle,Arc |

| Process table | single |

| Repeat precision | ±3μm |

| Cutting precision | ±20μm |

| Ambient Temperatur | 22℃±2℃(71.6℉±2℉) |

| Laser wavelength | 355nm/532nm |

| Platform | granite table |

| Automatic feeding | 3-Step track transfer |

| Receive Data Forma | Gerber, HPGL, Sieb & Meier, Excellon, ODB++ |

| Operation system | Windows 7 / Windows 10 |

| Target reads | CCD automatic target capture Target shape is irregular,

no Target, DIL is required Modules |

| Cutting software | DreamCreaTor |

| Data processing software | CircuitCAM 7 |

| XYZ-axis driving mode | linear +servo motor |

| Voltage/Power requirement | AC380V 50/60Hz 2.5KW three phase |

| Pneumatic pressure requirement | 0.6MPa,50L/min |

| Dimensions(W*D*H) | 940mm x 1,720mm x 1,650mm |

| Weight | 1500KG |