Features

1. Smooth Hole Sidewalls

Laser cutting produces smooth and even hole sidewalls, delivering superior quality results for stencil manufacturing applications.

2. High Precision and Quality

Achieves cutting accuracy with ±10μm hole positioning across the entire surface, ensuring precise and reliable output.

3. Micro-Hole Processing

Capable of cutting ultra-fine micro-holes with high precision, making it suitable for complex and detailed stencil patterns.

4. Fast and Efficient Operation

Operates at high speeds to boost production efficiency without compromising on cut quality, significantly reducing manufacturing time.

5. No Consumables Required

The ZAM3 and ZAM7 machines do not rely on consumables (such as blades or dies), which minimizes long-term operational costs. Additionally, there is no need for future equipment upgrades or add-on accessories.

6. Seamless MES Integration

Equipped with standard industrial interfaces, both machines can easily integrate into Manufacturing Execution Systems (MES). They support functionalities such as data collection, resource allocation, product tracking, and distribution. Customization is also available to match specific production line needs.

Look no further! The same machines used by world’s top 500companies

Send us a direct message now, justsend us a picture of your product andwe’ll be able to recommend the rightproduct for you right away.

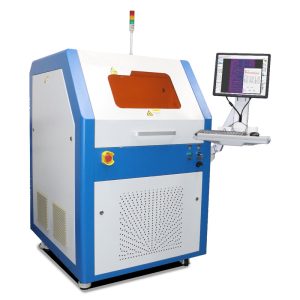

Specifications

| Feature | ZAM3 Stainless Steel Stencil Laser Cutting Machines | ZAM7 Stainless Steel Stencil Laser Cutting Machines |

|---|---|---|

| Laser Type | Imported IPG Infrared Laser, 200W | Imported IPG Infrared Laser, 200W |

| Max Processing Area | 600mm x 800mm (736*736mm Grid Frame) | 600mm x 800mm (736*736mm Grid Frame) |

| Platform | Granite Platform, Linear Motor | Granite Platform, Linear Motor |

| Data Processing Software | CircuitCAM 7 Pro | CircuitCAM 7 Pro |

| Machine Control Software | DreamCreaTor 3 | DreamCreaTor 3 |

| CCD Alignment System | CCD Automatic Alignment | CCD Automatic Alignment |

| X/Y Axis Positioning Accuracy | ≤ 2μm | ≤ 2μm |

| X/Y Axis Repeatability | ≤ 2μm | ≤ 2μm |

| X/Y Axis Resolution | 0.1μm | 0.1μm |

| Functions | Laser Cutting | Laser Cutting, Marking, Polishing, Screen Inspection |

| Cutting Gas Pressure | Compressed Air 1~1.6MPa | Compressed Air 1~1.6MPa |

| Machine Dimensions (W x H x D) | 1,480mm × 1,585mm × 1,713mm | 1,480mm × 1,585mm × 3,276mm |

| Machine Weight | Approx. 2000kg | Approx. 2500kg |

| Power Supply | 380VAC / 50Hz, 5.7kW | 380VAC / 50Hz, 6.5kW |

| Operating Temperature | 22°C ±2°C | 22°C ±2°C |