Features

-

10X Zoom-In Imaging

The system features a 10X zoom-in image function, making programming easier and significantly increasing the accuracy of point setting. -

Dual Sliding Tables

Equipped with two sliding tables that operate simultaneously for in-and-out movement, effectively reducing tack time and improving overall productivity. -

Auto Mark Offset System

The CCD image recognition system supports Auto Mark offset, allowing real-time path simulation and verification to minimize routing errors before cutting begins. -

Routing Bit Life Monitoring

Includes a routing bit life monitoring and alarm system, which alerts the operator after 120 meters of cutting. The bit is designed to use three segments (first 2mm, middle 2mm, and final 2mm) to extend its operational lifespan. -

CCD-Based Path Simulation

The CCD imaging system can simulate and verify cutting paths before execution, further reducing the chances of mistakes and enhancing cutting precision.

Advantages

-

Dual Sliding Platform: Equipped with a double-slide positioning system to minimize cutting wait times and significantly enhance production capacity.

-

Damage Prevention: Prevents issues such as tin cracking and component damage typically caused by manual board bending.

-

Low-Stress Cutting: Eliminates mechanical stress from blunt force or folding, ensuring safe and precise depaneling.

-

Versatile Cutting Capability: Suitable for cutting both arcs and straight lines on completed PCB panels.

-

Precision Cutting for Small Components: Ideal for final cutting of small PCB pieces such as mobile phone baseboards, PDAs, and PC interface cards.

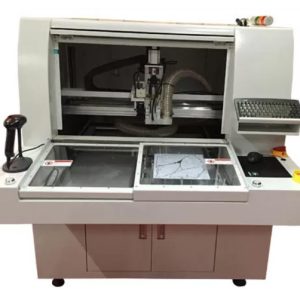

Specification

| Overall | |

| Dimensions(W*D*H) | 1370mm*1650mm*1450mm |

| Weight | 650KG |

| Height offset | 60~110mm |

| Manipulator | |

| Motor type | JiaBao series |

| Positioning repeatability | 0.001mm |

| Axis working area(max) | 830mm*580mm*50mm |

| Work station | |

| PCB fixation | standard,specialization |

| PCB loading/unloading | manual |

| PCB size (max) | 320*320mm |

| PCB thick (max) | 5mm |

| Fixturing | |

| Rigidity fixturing | Use client fixture |

| Fixturing fixation | machinery |

| Spindle Motor | |

| Power | 150W |

| Spindle | 60000rpm/min |

| Protect | self/wind cooling |

| Change cutter | Specialization |

| Routing capability | |

| Cutting speed(max.) | 80mm/s |

| Driving speed(max.) | 2500mm/s |

| Precision of cutting | 0.01mm |

| Vacuum System | |

| Vacuum power | 3.5KW AC 380V |

| Vacuum | plumb |

| Utilities | |

| Power | 2.0KW AC380V |

| Air supply | 4-6KG/cm2 |

| Programming | |

| Program edit | Inline |

| Function edit | Line,arc,circula,U-curve |

| Program storage | HDD |

| Vision system | SONE colour CCD |

| milling cutter offset | AUTO |

| Vacuum setup | AUTO |

| Operation Monitors | |

| Iindicator | Iindicator Machine state |

| tool check | Automatic detection tool life, the use of time testing |

| Motor protect | Have overheating, overload, low voltage protection function |

| motor over loading check | Have Overload, the line is normal, low voltage protection function |

| Tool usable time | Automatic detection tool life, |

| Data statistic | Separate board model, separating count, diverse counting methods |

| Error record | Software automatically records all alarms memory of machines |

| III. Accuracy | |

| Axis precision | 0.001mm |

| Cutting precision | 0.1mm |

| IV. Safety | |

| Working area protect | With four sealed protection |

| Door sensor | Front and rear safety door micro-switch sensor (optional) |