Features

●Easy to Use

-

One-Touch Operation

PCB depaneling can be initiated easily with the simple press of an external button, making it user-friendly. -

Point-and-Click Path Programming

Built-in image processing software allows operators to define cutting paths quickly using intuitive point-and-click technology. -

Automatic Alignment Compensation

The integrated CCD camera enables automatic alignment correction, ensuring precise cutting without manual adjustments. -

Low Maintenance Design

The machine is designed for easy access, repair, and cleaning, reducing downtime and maintenance requirements.

●High Value at Low Cost

-

Fast and Efficient Performance

Delivers high-speed operation and excellent cutting efficiency, ideal for high-volume PCBA production lines. -

User-Friendly Interface

Easy to operate even for non-specialists with minimal training, lowering labor requirements. -

Low Operating Costs

With robust construction and minimal need for servicing, the machine keeps maintenance costs very low. -

Excellent ROI

Combining strong performance, ease of use, and low ownership cost, this router provides exceptional value for money—making it a smart investment for any production facility.

Specification

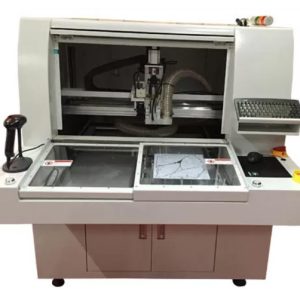

| Model | CW-F01 |

| Standard working area | 320*320mm |

| Power | 220V, 4.2KW |

| Manipulator Repeatability | ±0.02mm |

| Resolution | ±0.01mm |

| Board Positioning | Dual workstation with nest fixture or pin fixture |

| Panel Location | Located by tooling holes or edges of PCB |

| Loading | Manual |

| Unloading | Manual |

| Panel Size | 320*320mm(standard) |

| Panel Thickness | 0.5-3.5mm |

| Spindle motor | KAVO Spindle |

| Tool Change | Manual |

| Dust filtration system | 3KW Vacuum Cleaner |

| Vision system | High resolution CCD video camera |

| Programming | Vision assisted point to point manual teaching |

| Editing Function | Dry run vision assisted / test run mode |

| Machine weight | 500kgs |

| Machine dimension | 113*140*108cm |