Features

●Fully Automated PCB Handling

Supports automatic loading, cutting, and unloading of PCBs, with multiple solution options available to meet various process requirements.

●CCD Vision Positioning and Alignment

Utilizes a CCD system for offset correction and precise alignment to ensure high cutting accuracy.

●High-Speed Spindle with Auto Tool-Change

Equipped with a high-speed spindle featuring automatic tool-change, which helps reduce static-induced PCBA damage and improves production efficiency.

●Patented Flexible Cleaning Brush

Features a patented cleaning brush that allows segmented use of the milling tool, significantly extending its service life.

●Optional Dual-Spindle High-Efficiency Models

High-efficiency dual-spindle models—GAM320AD, GAM330AD, and GAM340AD—are available for customers requiring greater throughput.

Optional

- Optional clamping module for carrier process

- The height checking module in laser

- Barcode reader

- Milling tool diameter detection

- The customized MES

Look no further! The same machines used by world’s top 500companies

Send us a direct message now, justsend us a picture of your product andwe’ll be able to recommend the rightproduct for you right away.

Specifications

| Model | GAM320AT |

|---|---|

| Valid cutting size | 350*300mm |

| Loading method | Track delivery |

| Unloading method | Belt delivery or track delivery |

| Transfer method | Vacuum nozzle absorption |

| Movement direction | Left to right or right to left |

| Cutting function | Tweening to straight line, L shape, U shape, Circle, Arc |

| Process table | Dual tables |

| Repeat precision | ±0.01mm |

| Cutting precision | ±0.05mm |

| Max moving speed | XY: 1000mm/sec, Z: 800mm/sec |

| Max moving trip | X: 790mm, Y: 440mm, Z: 90mm |

| Spindle’s speed | MAX: 60000rpm (Adjustable) |

| Tool change type | Auto tool change |

| Cutting speed | 1-100mm/s (Adjustable) |

| Operating system | Windows 10 |

| Program teaching mode | Intuitive teaching by CCD color image input |

| Program backup | USB data transfer |

| Control method | Precision multi-axis control system |

| XYZ axis driving mode | AC Servo motor |

| Size of milling tool | 0.8-3.0mm |

| Voltage/Power requirement | AC220V 50/60Hz 4KW Single-phase |

| Pneumatic pressure requirement | 0.6MPa, 155L/min |

| Dimensions(W*D*H) | 1949*1192*1705mm |

| Weight | 750kg |

| Collector | TS200L |

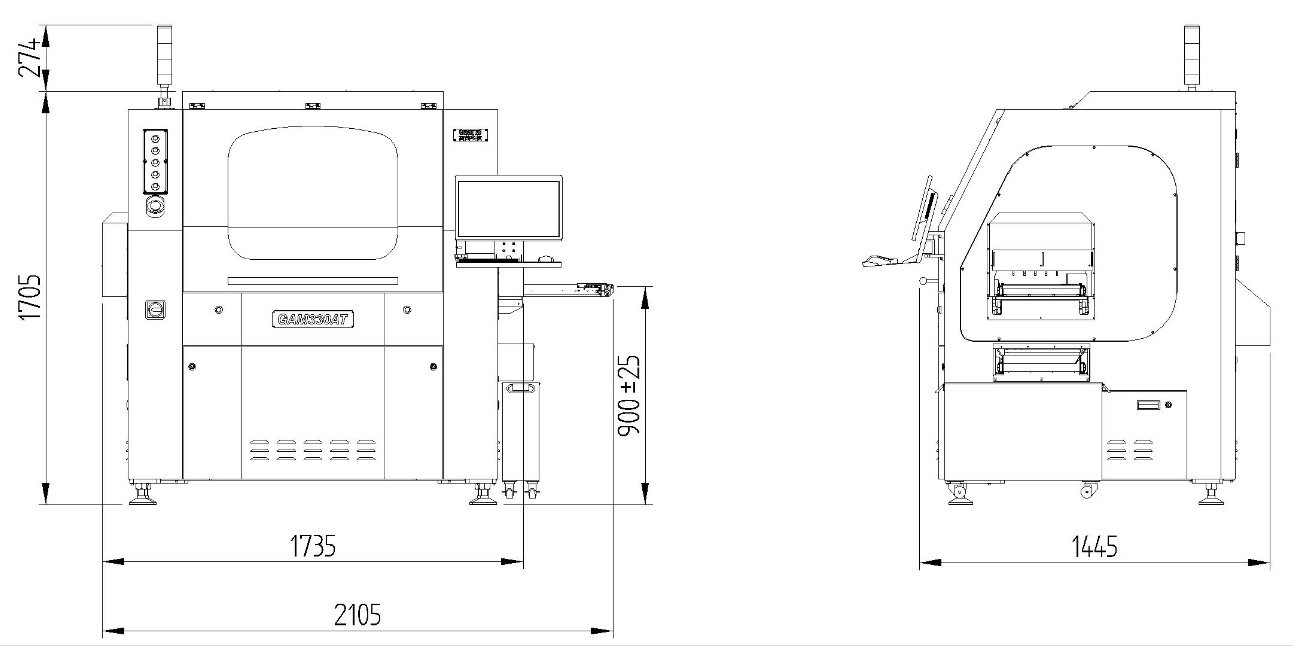

Front View/Side View