Features

-

Dual-Direction Depaneling

-

Supports both horizontal and vertical PCB depaneling, enabling inline cutting of irregular-shaped panels in one operation.

-

-

High Automation Capability

-

Can integrate with PCB loaders and unloaders, minimizing the need for manual labor and improving production efficiency.

-

-

User-Friendly Touch Screen Interface

-

Allows quick and easy product switching with a simple and intuitive touch-screen control system.

-

-

PLC Program Storage

-

Equipped with a PLC control system that can store up to 100 programs, enabling flexible handling of multiple product types.

-

-

Selectable Single-Direction Depaneling Mode

-

Offers the option to set depaneling direction (horizontal or vertical) individually via touch screen, making the system more versatile.

-

-

Optional Dust Cleaner

-

A dust removal unit can be optionally connected to maintain a cleaner working environment and reduce particulate buildup.

-

Specifications

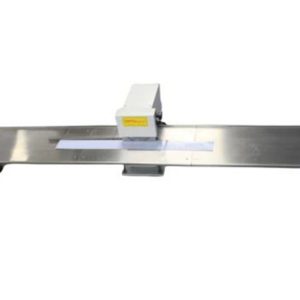

| Name | V-Cut PCB Separator |

|---|---|

| Blade Dimension | Linear Blade Or Circluar Blades |

| Machine Color | White |

| Blade Material | High Speed Steel |

| V-cut Angel | >40° |

| Cutting Speed | 300-500/s |

| Dimension | 1250(1560)mm×800mm×1295mm |

| PCB Width | 300mm(could Be Customized) |

| Type | Hay Cutter / Multi Cutter / V Cut PCB Separator |

| Packaging Weight | 300kgs |

Support and Services

We offer comprehensive technical support and services for our V-Cut PCB Separator. Our team of experienced professionals is ready to assist you with any product-related inquiries. Our support includes:

-

Troubleshooting guidance and effective solutions

-

Installation and operation instructions

-

Detailed product specifications and parameters

-

Maintenance and repair assistance

-

Replacement parts and accessories

In addition, we provide a full warranty to ensure your V-Cut PCB Separator operates safely and efficiently.

If you have any questions or need assistance, please don’t hesitate to contact us.

Packing and Shipping

The V-Cut PCB Separator is securely packaged to prevent damage during transit. It is first placed in a sturdy cardboard box with protective foam inserts to cushion the product. The box is then sealed with tape to ensure it remains closed during shipping. For added protection, it is placed inside a larger outer carton and shipped using a reliable logistics provider to ensure safe and timely delivery to its destination.

Applications

The PCBA V-Cut Depaneling Machine is a high-efficiency, CE-certified PCB separator made in China. This inline depaneling system is designed for cutting printed circuit boards (PCBs) with V-cut grooves and supports PCB widths up to 300mm (customizable).

Featuring a quick-change blade set and a durable, heavy-duty frame, the CWVC-5 delivers precise, safe, and efficient depaneling. It is powered by a 220V or 110V, 50Hz power supply, and includes a digital display for simplified operation and maintenance.

This machine is suitable for high-volume production and supports a wide range of PCB materials. It is widely used in industries such as automotive, aerospace, telecommunications, medical devices, and consumer electronics.

Key Features:

-

Inline V-cut PCB separator with quick-change blade system

-

Supports PCB widths up to 300mm (customizable)

-

High-precision cutting with minimal stress on boards

-

Durable frame and powerful motor ensure long-term reliability

-

Digital interface for easy operation and maintenance

-

CE Certified and built for industrial-grade performance

Product Details:

-

Power Supply: 220V/110V, 50Hz

-

Color: White

-

Minimum Order Quantity: 1 set

-

Packaging: Export wooden case

-

Delivery Time: 8–15 days after payment

-

Supply Capacity: 30 sets per month

-

Price: Negotiable