As electronic devices like phones and medical tools get smaller and more advanced, making circuit boards needs to be more careful and precise. One important step is depaneling, which means cutting out individual boards from a bigger sheet. Old methods, like using saws or blades, can cause damage to the boards. Laser depaneling is a new and better way. It uses a powerful beam of light to cut the boards without touching them, making smooth and accurate cuts that keep parts safe.As a professional with over ten years of experience in the PCB depaneling industry, I will explain the definition and working principle of laser depaneling, as well as how it compares with mechanical methods in this article.

What is laser depaneling?

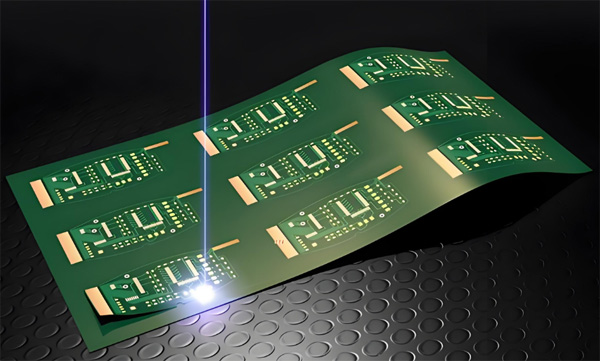

Laser depaneling is a way to cut circuit boards out of a larger panel using a laser. Unlike saws or other tools that touch the board, the laser cuts without touching it. This helps avoid damage and makes very clean, accurate cuts. It works well for small or fragile boards, like those in phones or medical devices. Since there are no blades, there’s nothing to wear out, so the process stays consistent and needs less maintenance. Overall, laser depaneling is a safer and more precise way to separate circuit boards.

How does PCB laser depaneling work?

●Laser Beam is Focused

A machine focuses a tiny, powerful laser beam (often ultraviolet or infrared) onto the panel of PCBs.

●Laser Follows a Path

The laser moves along a pre-set path, cutting through the panel material (like FR4 or flexible plastic) to separate the individual circuit boards.

●Material is Vaporized

The laser’s heat is strong enough to vaporize or burn away the board material where it hits, making a precise cut without touching anything.

●No Mechanical Stress

Since there’s no cutting blade, the boards don’t bend, crack, or shake—this helps protect small components and keeps everything in place.

●Minimal Heat Spread

Special laser types (like UV lasers) focus the heat in a very small area, so nearby parts don’t get hot or damaged.

●Clean, Precise Cuts

The result is a clean edge with no dust, roughness, or leftover material.

How does laser depaneling compare to mechanical methods?

Laser Depaneling vs. Mechanical Methods

| Feature | Laser Depaneling | Mechanical Depaneling |

|---|---|---|

| Cut Quality | Very clean and smooth | May leave rough edges or small cracks |

| Board Damage | Very low risk (no contact) | Higher risk (vibration, pressure) |

| Shape Flexibility | Can cut any shape, even curves | Mostly straight lines or simple shapes |

| Tool Wear | No wear (uses light) | Tools wear out and need replacing |

| Heat Spread | Very small heat-affected area | Usually no heat, but mechanical stress |

| Dust/Debris | No debris (material vaporizes) | Creates dust, needs cleaning |

| Speed | Slightly slower for some materials | Usually faster for simple cuts |

| Cost | Higher upfront cost (laser machine) | Lower cost, but tools wear out |

Seprays’Laser PCB Depaneling Solutions

DirectLaser H1 High-Precision Laser Cutting Machine

The DirectLaser H1 is a state-of-the-art laser cutting machine engineered for high-precision, high-speed, and clean processing of printed circuit boards (PCBs) and other materials. Designed with a strong emphasis on automation, safety, and versatility, it delivers outstanding performance for modern electronics manufacturing.

DirectLaser S2 PCB/FPC Laser Cutting Machine

The DirectLaser S2 PCB/FPC Laser Cutting Machine by SEPRAYS is a high-precision, high-quality solution designed to meet the growing demands of modern electronics manufacturing. As electronic devices become increasingly smaller and more complex, the need for accurate and dependable depaneling and cutting solutions has never been more critical.

Conclusion

Laser depaneling is a safer and more exact way to cut circuit boards, especially when they are small or delicate. While older cutting methods may be faster or cheaper for simple jobs, laser machines give better results for today’s high-tech electronics. Tools like Seprays’ DirectLaser H1 and S2 show how this technology helps make clean, fast, and reliable cuts. As more devices get smaller and more complex, laser depaneling is becoming the best choice in precision electronics manufacturing.

A professional with over a decade of experience in the PCB depaneling industry.