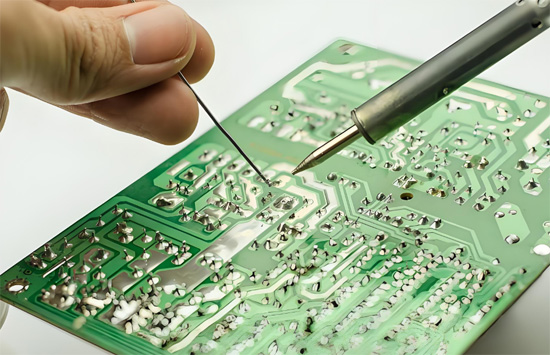

If you’ve ever done a bit of soldering, you’ve probably noticed that sticky, brownish stuff left behind—yep, that’s flux. While it helps during soldering, it’s not meant to stick around. I’ve had my fair share of messy boards, and trust me, cleaning off the flux makes a big difference. In this guide, I’ll walk you through easy and effective ways to clean it up so your PCB looks sharp and works like a charm.

- Part 1. What is the best way to clean flux off a PCB?

- Part 2. Can I use isopropyl alcohol to remove flux from circuit boards?

- Part 3. Do I need to clean off no-clean flux?

- Part 4. What happens if you don’t remove flux from a PCB?

- Part 5. How do professionals clean flux residue in PCB assembly?

- Part 6. Is it safe to clean flux with a toothbrush?

- Part 7. What type of brush is best for cleaning flux?

- Part 8. How do I remove flux from under SMD components?

- Part 9. Can flux residue cause corrosion or electrical issues?

- Part 10. What tools are needed to clean flux from a PCB?

- Part 11. FAQs about Clean Flux off a PCB

Part 1. What is the best way to clean flux off a PCB?

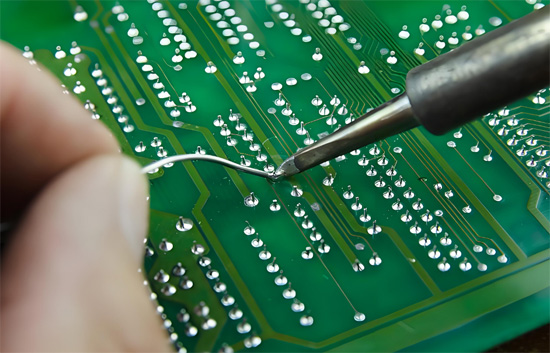

The best way to clean flux off a PCB is by using isopropyl alcohol (preferably 90% or higher) and a soft, anti-static brush. Gently scrub the affected area to dissolve the flux, then wipe or dab it dry with lint-free cloths or swabs. For sensitive boards or mass production, professional tools like ultrasonic cleaners or dedicated flux removers may be used.

Part 2. Can I use isopropyl alcohol to remove flux from circuit boards?

Yes, isopropyl alcohol (IPA) is widely used for removing flux due to its effectiveness and low residue. Use 90% or higher concentration for best results. Apply it with a soft brush or swab, and make sure the board is fully dry before powering on.

Part 3. Do I need to clean off no-clean flux?

No-clean flux is designed to leave minimal, non-conductive, and non-corrosive residue. However, cleaning is still recommended in critical applications or where aesthetic appearance, reliability, or coating is important, such as aerospace, medical, or high-frequency circuits.

Part 4. What happens if you don’t remove flux from a PCB?

Leaving flux on a PCB can attract moisture and dirt, leading to corrosion, electrical leakage, or signal interference over time. This is especially true for rosin-based or water-soluble flux. Even no-clean flux can cause issues in high-reliability or harsh environments.

Part 5. How do professionals clean flux residue in PCB assembly?

Professionals use automated cleaning systems like batch washers, in-line cleaners, or ultrasonic baths with specialized solvents. These methods ensure thorough cleaning, especially for high-density or sensitive boards. Manual cleaning is still used for prototypes or small runs.

Top FAQs About Cleaning PCB Boards

Part 6. Is it safe to clean flux with a toothbrush?

A soft-bristled toothbrush can be used to scrub away flux, but it should be ESD-safe to avoid static damage. Avoid using worn or stiff brushes that might scratch or dislodge components. Always combine with proper solvents like IPA for safe and effective cleaning.

Part 7. What type of brush is best for cleaning flux?

An anti-static (ESD-safe) brush with soft nylon or natural bristles is best for cleaning flux. It should be stiff enough to loosen residues but gentle enough not to damage components. Use different sizes for general surfaces and tight areas around components.

Part 8. How do I remove flux from under SMD components?

To remove flux from under SMDs, use a high-purity IPA and a fine-bristled brush. Tilt the board to let solvent flow out. For deeper cleaning, ultrasonic cleaners or pressure rinsing with defluxing agents are more effective in reaching under tight component leads.

Part 9. Can flux residue cause corrosion or electrical issues?

Yes, especially rosin-based or water-soluble flux residues. These can absorb moisture, leading to corrosion, dendrite growth, or leakage currents. Even no-clean flux may become problematic in high-humidity or high-voltage environments if not removed properly.

Part 10. What tools are needed to clean flux from a PCB?

Basic tools include high-purity isopropyl alcohol, ESD-safe brushes, lint-free wipes, swabs, and safety gear like gloves. For more advanced or automated cleaning, tools like ultrasonic cleaners, spray systems, or defluxing stations are used in industrial settings.

Part 11. FAQs about Clean Flux off a PCB

How do I clean flux off a PCB without alcohol?

Use commercial flux removers, deionized water (for water-soluble flux), or citrus-based cleaners. Always ensure compatibility with your PCB and components.

Are there any flux removers better than isopropyl alcohol?

Yes, commercial flux removers like Chemtronics or MG Chemicals are stronger and evaporate faster, leaving less residue than IPA.

Can ultrasonic cleaners be used to remove flux?

Yes, ultrasonic cleaners with proper solvents are effective for removing flux, especially under dense or small components.

How soon should flux be cleaned after soldering?

Ideally within 1–2 hours. The longer it sits, the harder it is to remove, especially for rosin-based fluxes.

What’s the safest way to clean flux from sensitive PCBs?

Use high-purity IPA or specialized cleaners with soft, ESD-safe brushes. Avoid harsh chemicals and mechanical abrasion.

How do I clean rosin flux vs. no-clean flux?

Rosin flux needs IPA or dedicated removers. No-clean flux often doesn’t require cleaning but can be removed with stronger solvents if needed.

Can flux be cleaned with water and soap?

Only if the flux is water-soluble. For rosin or no-clean types, water and soap are ineffective and may damage the PCB.

Is baking soda or vinegar safe for cleaning PCB flux?

No. These household items can leave residue or corrode metals. Use electronics-grade solvents instead.

What are common mistakes when cleaning flux?

Using wrong solvents, too much force, non-ESD brushes, or not drying the board properly can cause damage or leave residues.

How do I clean flux residue during rework or repair?

Use IPA and a swab or brush immediately after soldering. Clean before adding new components to avoid buildup and corrosion.

A professional with over a decade of experience in the PCB depaneling industry.