Router depaneling is currently one of the most widely used methods for PCB separation. It offers broader application capabilities than V-cut depaneling and is more cost-effective than laser depaneling. In this article, we’ll explore the key features and advantages of router depaneling to help you understand why it’s such a popular choice.

- Part1. What is router depaneling in PCB manufacturing?

- Part2. How does a PCB router depaneling machine work?

- Part3. What are the main advantages of router depaneling?

- Part4. What types of PCBs are suitable for router depaneling?

- Part5. What safety precautions are needed for router depaneling machines?

- Part6. What are the limitations of router depaneling?

- Part7. How precise is router depaneling compared to laser cutting?

- Part8. How do you maintain or calibrate a router depaneling machine?

- Part9. What kind of router bits are used for PCB depaneling?

- Part10. How long do router bits typically last in depaneling applications?

- Part 11. FAQs about router depaneling

Part1. What is router depaneling in PCB manufacturing?

Router depaneling is a process used to separate individual printed circuit boards (PCBs) from a larger panel after assembly. It uses a high-speed rotating bit—similar to a tiny drill or mill—to cut along pre-defined paths between boards. This method avoids mechanical stress on components and allows for complex cutting shapes.

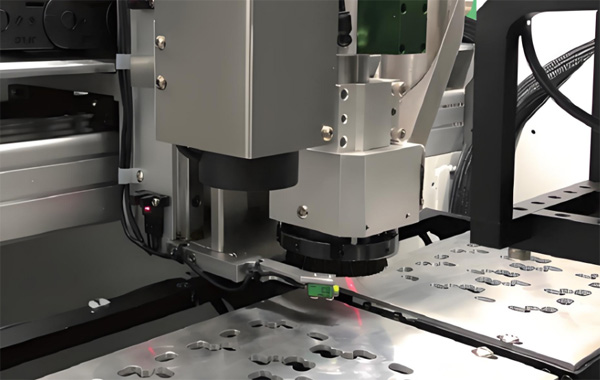

Part2. How does a PCB router depaneling machine work?

A PCB router depaneling machine uses a CNC-controlled spindle to move a cutting bit along programmed paths between circuit boards. The PCB panel is securely held in place, and the router bit cuts the material—usually FR4 or similar—leaving clean, accurate edges. Dust is collected by a vacuum system during cutting.

Part3. What are the main advantages of router depaneling?

Router depaneling is flexible, precise, and causes minimal stress to the PCB. It supports complex shapes and closely placed components. Unlike V-cut or punching, it doesn’t require straight lines or simple designs. It also avoids cracking or damaging parts, making it ideal for sensitive or high-density boards.

Part4. What types of PCBs are suitable for router depaneling?

Router depaneling works well with rigid, rigid-flex, and some thicker PCBs. It is ideal for medium to high-density boards and irregular or curved outlines. It’s not recommended for ultra-thin or very soft materials, which might flex or tear under the cutting force.

Part5. What safety precautions are needed for router depaneling machines?

Operators should wear safety glasses and hearing protection. Machines should include dust extraction systems and safety enclosures. Proper training is needed to avoid injury from the high-speed bit. Maintenance should only be performed when the machine is powered off and locked out.

Part6. What are the limitations of router depaneling?

Router depaneling produces dust, which requires a strong vacuum system. Bit wear over time affects cutting quality and requires regular replacement. It’s slower than punching or V-cut in large volumes and may not suit very thin or flexible boards due to vibration and potential tearing.

Part7. How precise is router depaneling compared to laser cutting?

Laser cutting is generally more precise, with micron-level accuracy and zero mechanical contact. Router depaneling offers high accuracy too, usually within ±50–100 microns, but not as fine as a laser. Still, it is sufficient for most electronics and allows for more affordable processing.

Part8. How do you maintain or calibrate a router depaneling machine?

Maintenance includes cleaning dust filters, inspecting spindles, and replacing worn router bits. Calibration involves aligning the cutting path with the PCB layout, checking bit depth, and ensuring the fixture holds boards firmly. Regular software updates and spindle checks help maintain accuracy.

Part9. What kind of router bits are used for PCB depaneling?

Router bits are usually made of carbide and come in sizes from 0.8mm to 3.2mm, depending on the required cut width. Single- or double-flute designs are common. The bit shape and size depend on the material thickness, cut complexity, and desired edge finish.

Part10. How long do router bits typically last in depaneling applications?

Router bit life in PCB depaneling depends on the material being cut, bit type, and cutting speed. On average, a high-quality carbide bit can last for 5,000 to 10,000 cuts on standard FR4 boards. However, the lifespan decreases when cutting thicker or harder materials like metal-core PCBs. Regular inspection is important—worn bits can cause poor edge quality, burrs, or damage to the board. To maintain consistent results, manufacturers often track usage cycles and replace bits proactively.

Part 11. FAQs about router depaneling

1. What is the recommended distance between the routed edge and PCB components?

Keep components at least 1 mm from the routed edge to avoid vibration and cutting stress.

2. Can router depaneling handle curved or irregular shapes?

Yes, routers can cut complex shapes with high precision using programmable paths.

3. How does router depaneling affect PCB stress and reliability?

It causes minimal mechanical stress, helping maintain PCB strength and reliability.

4. Can router depaneling be fully automated?

Yes, many router machines support full automation with robotic arms and conveyors.

5. Is router depaneling suitable for high-volume production?

Yes, it’s widely used in mass production for its accuracy, speed, and repeatability.

6. Does router depaneling generate dust or debris?

Yes, it creates dust, so machines need vacuum systems to collect debris during cutting.

7. What factors affect the speed of router depaneling?

Material hardness, thickness, bit quality, cutting speed, and path complexity.

8. What industries commonly use router depaneling?

Electronics, automotive, medical, telecom, and consumer device manufacturing.

9. How is router depaneling different from V-cut or laser depaneling?

Router uses a spinning bit; V-cut scores and snaps; laser cuts with heat and no contact.

10. What features should I look for in a PCB router depaneling machine?

Look for precision cutting, dust extraction, tool monitoring, automation, and easy setup.

A professional with over a decade of experience in the PCB depaneling industry.