I’ll be honest — the first time I tried to fix a circuit board, I nearly turned it into modern art. Sparks flew (literally), and I learned very quickly that “just add more solder” is not a valid repair strategy. Over time — and after a few burned fingertips — I picked up what actually works. So, if you’ve ever stared at a fried PCB and wondered whether it’s salvageable, this guide is for you.

- Part 1. What is circuit board repair?

- Part 2. How do I diagnose a faulty PCB?

- Part 3. What tools are needed for circuit board repair?

- Part 4. How do I remove a part from a PCB (desoldering)?

- Part 5. How do I solder components back onto a PCB?

- Part 6. What is rework in circuit board repair?

- Part 7. How do I fix broken traces on a circuit board?

- Part 8. Can I repair a cracked PCB substrate?

- Part 9. How do I repair lifted pads or vias?

- Part 10. How do I fix corrosion or oxidation on a PCB?

- Part 11. FAQs about Circuit Board Repair

Part 1. What is circuit board repair?

Circuit board repair involves diagnosing and fixing damaged or malfunctioning printed circuit boards (PCBs). It can include replacing components, repairing traces, removing corrosion, or restoring connections to bring the board back to working condition without full replacement.

Part 2. How do I diagnose a faulty PCB?

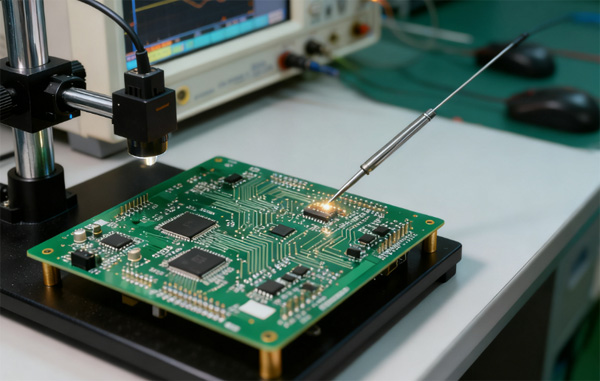

Diagnosis starts with visual inspection for burns, cracks, or corrosion, followed by using a multimeter to test voltage, continuity, and resistance. Thermal cameras or oscilloscopes help identify short circuits, faulty components, or broken traces that may cause circuit failure.

Part 3. What tools are needed for circuit board repair?

Essential tools include a soldering iron, desoldering pump, hot air rework station, tweezers, magnifier or microscope, multimeter, flux, solder wire, cleaning brushes, and ESD protection. Advanced repairs may require reflow ovens or microscopes for SMD components.

Part 4. How do I remove a part from a PCB (desoldering)?

To desolder, heat the component’s solder joints using a soldering iron or hot air gun until the solder melts. Use a desoldering pump or braid to remove excess solder, then gently lift the component. Avoid excessive heat to prevent pad or trace damage.

Part 5. How do I solder components back onto a PCB?

Clean the pads, apply flux, and position the component correctly. Heat the joint with a soldering iron and apply solder to create a smooth, shiny connection. Avoid using too much solder or heat. For SMD parts, use hot air or reflow techniques for even heating.

Part 6. What is rework in circuit board repair?

Rework refers to modifying, correcting, or replacing components on an assembled PCB to fix defects or update design errors. It can involve desoldering and resoldering parts, reflowing solder joints, or adding jumper wires to correct circuit design issues.

Part 7. How do I fix broken traces on a circuit board?

Locate the break using a multimeter. Scrape off the solder mask to expose copper, then solder a small wire or copper foil bridge to reconnect the trace. Cover the repaired area with epoxy or solder mask to protect it from oxidation and mechanical damage.

Part 8. Can I repair a cracked PCB substrate?

Yes, minor cracks can be repaired by cleaning the area, applying epoxy resin, and reinforcing the damaged section with fiberglass or copper tape. For electrical continuity, solder small wires across the broken traces. Severely cracked boards may need replacement.

Part 9. How do I repair lifted pads or vias?

Clean the damaged area and secure the lifted pad with epoxy. Once cured, reconnect it with fine wire to the trace or via. If a via is damaged, use a micro jumper wire to recreate the connection between layers. Handle gently to avoid further lifting.

Part 10. How do I fix corrosion or oxidation on a PCB?

Remove corrosion using isopropyl alcohol and a soft brush. For severe oxidation, use a fiberglass pen or mild acid cleaner to expose clean copper. After cleaning, re-tin the area with solder and apply protective coating to prevent future corrosion.

Part 11. FAQs about Circuit Board Repair

How do I repair a short circuit on a PCB?

Use a multimeter to locate the shorted area, visually inspect for solder bridges or debris, and carefully remove excess solder with a wick. Replace any damaged components and retest continuity before powering the board.

What safety precautions should I take when repairing PCBs?

Always disconnect power, use ESD protection, work in a ventilated area, and wear eye protection. Handle hot tools and chemicals carefully to avoid burns or inhalation hazards.

How do I test a repaired circuit board?

Perform continuity and resistance checks with a multimeter, then power the board through a current-limited supply. Verify voltage levels, signal integrity, and functionality under normal operating conditions.

When should I replace rather than repair a board?

Replace when the PCB has severe burn damage, multiple broken layers, or repair costs exceed replacement value. Complex multilayer boards are often not economical to fix.

Can I repair surface-mounted devices (SMDs)?

Yes. Use a hot air rework station or soldering iron with fine tips. Carefully remove and replace the SMD, ensuring correct alignment and solder joint integrity.

How do I repair microvias or blind vias?

Microvias are hard to repair directly. Use micro jumper wires to reestablish connections between layers. Professional repair may require laser drilling and plating.

What is pad cratering and can it be repaired?

Pad cratering is substrate cracking beneath pads. Minor damage can be reinforced with epoxy and wire jumpers, but severe cases may require board replacement.

How do I restore solder mask after repair?

Clean the repaired area, apply UV-curable solder mask or epoxy, and cure it under UV light. This restores insulation and protects against oxidation.

How to handle BGA (ball grid array) component repairs?

Use a BGA rework station for precise heating. Remove the chip, reball or replace it, and reflow under controlled temperature. Verify alignment and connectivity with X-ray or AOI.

What are common mistakes to avoid during circuit board repair?

Avoid overheating components, lifting pads, excess solder, and skipping ESD precautions. Always verify polarity, continuity, and cleanliness before powering the board.

A professional with over a decade of experience in the PCB depaneling industry.