Cleaning a PCB (printed circuit board) might sound tricky, but it’s actually pretty simple if you do it the right way. I’ve cleaned many boards myself and learned a few easy tricks. In this guide, I’ll show you safe and simple ways to remove dust, dirt, or flux from your PCB using basic tools like isopropyl alcohol, soft brushes, and a little care.

- Part 1. How do you clean a PCB safely?

- Part 2. What is the best solution to clean a circuit board?

- Part 3. Can I use isopropyl alcohol to clean a PCB?

- Part 4. What tools are needed to clean a circuit board?

- Part 5. How do you remove dust from a PCB?

- Part 6. How to clean a burnt circuit board?

- Part 7. Can I clean a PCB with water?

- Part 8. How do professionals clean PCBs in manufacturing?

- Part 9. How to clean corrosion from a circuit board?

- Part 10. What’s the safest way to clean a PCB with components on it?

- Part 11. FAQs About Clean PCB Board

Part 1. How do you clean a PCB safely?

To clean a PCB safely, disconnect power and remove any batteries. Use 90% or higher isopropyl alcohol and an ESD-safe brush to gently scrub away dirt or residue. Avoid excessive pressure to protect components. Allow the board to dry completely before reassembly or powering on.

Part 2. What is the best solution to clean a circuit board?

The most commonly used and effective solution is high-purity (90%–99%) isopropyl alcohol. It evaporates quickly, leaves no residue, and safely dissolves oils, flux, and grime. For specialized needs, commercial PCB cleaners or defluxers are also excellent choices.

Part 3. Can I use isopropyl alcohol to clean a PCB?

Yes, isopropyl alcohol (IPA) is safe and effective for cleaning PCBs. Use a high concentration (90% or above) with a soft brush or swab. It cleans off flux, dust, and oils without damaging components and evaporates quickly, minimizing moisture risk.

Detailed Steps and Tips for Cleaning PCBs

Part 4. What tools are needed to clean a circuit board?

Basic tools include high-purity IPA, ESD-safe brushes, lint-free cloths, cotton swabs, and gloves. For advanced cleaning, ultrasonic cleaners, compressed air, and commercial PCB cleaning sprays can also be used, especially in manufacturing or repair shops.

Part 5. How do you remove dust from a PCB?

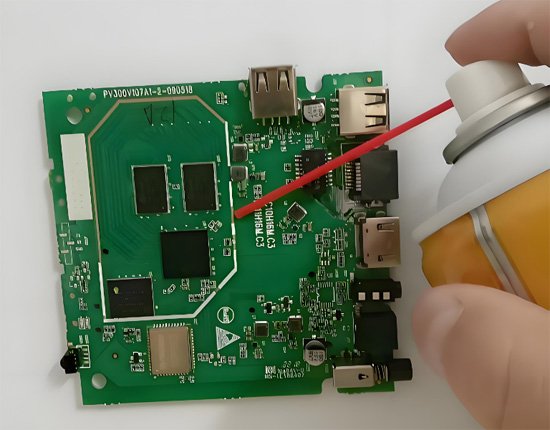

Use a can of compressed air or a soft, ESD-safe brush to gently remove dust. Avoid using vacuum cleaners with plastic tips or regular brushes, which may generate static electricity. If needed, follow up with a light IPA cleaning for sticky residues.

Part 6. How to clean a burnt circuit board?

First, power off and inspect the board. Carefully scrape away charred residue with a plastic tool or brush. Clean with IPA to remove soot or debris. If traces are damaged, you may need to repair or replace them. Severely burned boards often need full replacement.

Part 7. Can I clean a PCB with water?

Only use water if the PCB has water-soluble flux and no powered components. Distilled water is preferred. Avoid tap water due to minerals that can cause corrosion. Always dry thoroughly and consider using IPA afterward to remove remaining moisture.

Part 8. How do professionals clean PCBs in manufacturing?

Professionals use automated systems like batch cleaners, in-line defluxing machines, or ultrasonic cleaners with specialized solvents. These methods ensure thorough and repeatable cleaning for large volumes or sensitive boards, followed by drying and inspection.

Part 9. How to clean corrosion from a circuit board?

Use a soft brush with IPA to gently scrub off corrosion. For tough spots, mix baking soda and distilled water into a paste, apply carefully, then rinse with IPA. If corrosion has damaged traces or pads, repair may be required using solder or jumper wires.

Part 10. What’s the safest way to clean a PCB with components on it?

Use high-purity IPA with a soft ESD-safe brush or swab. Avoid spraying directly into connectors or sockets. Work in a static-safe area, and dry the board fully before reapplying power. Avoid aggressive chemicals or tools that might damage fragile parts.

Part 11. FAQs About Clean PCB Board

How do you clean flux residue off a PCB?

Use isopropyl alcohol (90%+) and an ESD-safe brush to gently scrub the flux. Wipe away residue with lint-free wipes or swabs. Dry thoroughly before powering.

Can ultrasonic cleaners be used for PCB cleaning?

Yes, they work well with the right cleaning fluid, especially for removing flux under components. Avoid using on boards with loose or delicate parts.

How to dry a PCB after cleaning?

Let it air dry in a dust-free area or use compressed air to speed up drying. Ensure it’s completely dry before applying power to avoid shorts.

Is vinegar safe for cleaning a PCB?

No, vinegar is acidic and can damage components or leave conductive residues. Stick to electronics-grade cleaners like isopropyl alcohol.

What should I avoid when cleaning a PCB?

Avoid static-prone tools, harsh chemicals, water with minerals, and too much force. Never power the board while wet or cleaning.

How do I clean a PCB after soldering?

Wait for it to cool, then clean flux with IPA and a soft brush. Wipe gently with lint-free swabs or cloths. Check for residue before drying.

Can I use a toothbrush to clean a circuit board?

Yes, if it’s a soft-bristled, anti-static brush. Regular toothbrushes may create static or be too harsh for delicate parts.

How to clean a PCB damaged by liquid spill?

Disconnect power, rinse with distilled water or IPA, gently brush, and dry thoroughly. Inspect for corrosion or damage before reuse.

Are there commercial PCB cleaning sprays?

Yes, sprays like flux removers and contact cleaners are made for PCBs. They’re fast-drying and safe for most electronics when used properly.

What precautions should I take when cleaning a PCB?

Power off, use ESD protection, work in a clean area, and avoid harsh chemicals. Always dry completely and inspect before powering up.

A professional with over a decade of experience in the PCB depaneling industry.