Features

●Fully Automated Operation

Supports automatic loading, cutting, and unloading of PCBs, with multiple solutions available to meet diverse process requirements.

●CCD Vision Alignment for Precision

Utilizes CCD vision positioning for offset correction and alignment, ensuring high cutting accuracy.

●High-Speed Spindle with Auto Tool-Change

Equipped with a high-speed spindle featuring automatic tool-change to reduce downtime and minimize PCBA damage caused by static electricity.

●Patented Flexible Cleaning Brush

A patented flexible cleaning brush design allows segmented use of the milling tool, significantly extending its service life.

●Optional Dual-Spindle High-Efficiency Models

High-efficiency dual-spindle models such as GAM320AD, GAM330AD, and GAM340AD are available for customers requiring higher throughput.

Optional

- Optional clamping module for carrier process

- The height checking module in laser

- Barcode reader

- Milling tool diameter detection

- The customized MES

Look no further! The same machines used by world’s top 500companies

More than one thousand well-known enterprises chose Seprays separator and established long-term cooperation.

Send us a direct message now, justsend us a picture of your product andwe’ll be able to recommend the rightproduct for you right away.

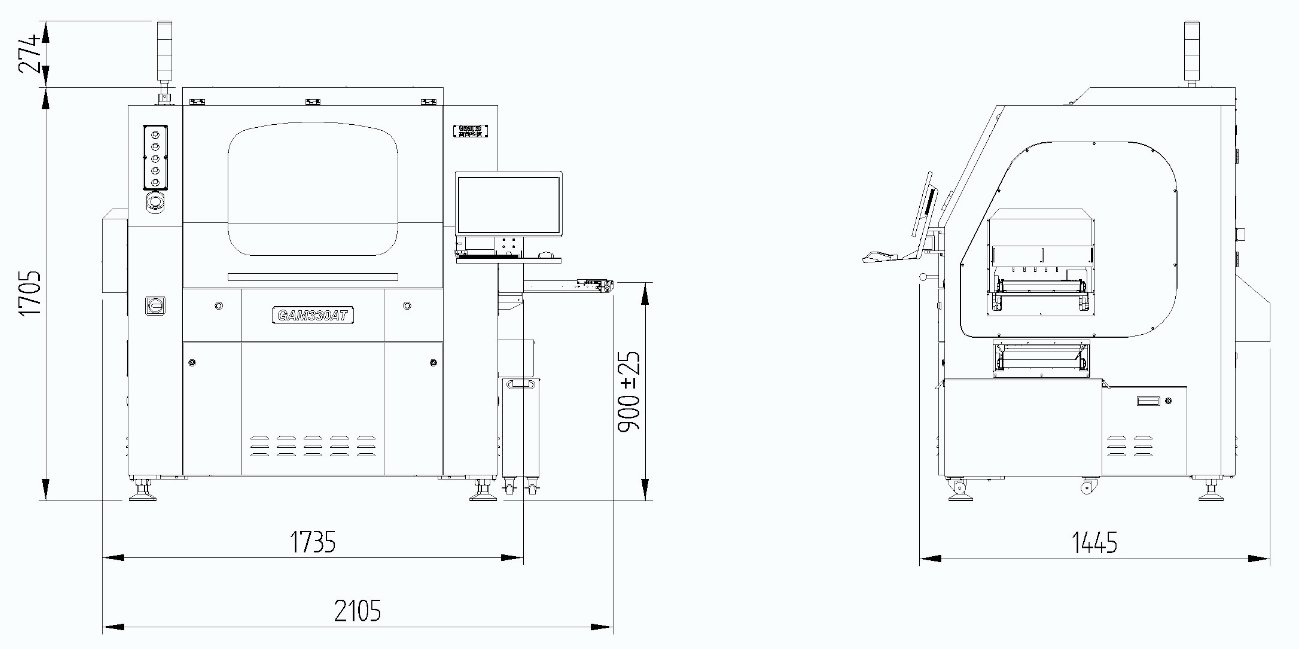

Front View/Side View