When I first started learning circuit board design, I quickly realized that creating a functional PCB is both an art and a science. This guide explains each stage of the process, from schematic creation to Gerber file preparation, covering essential techniques, materials, and best practices used in modern PCB design.

- Part 1. What is circuit board design?

- Part 2. How do I start designing a circuit board?

- Part 3. What software is best for PCB design?

- Part 4. What are the basic steps in circuit board design?

- Part 5. How do I create a schematic for a PCB?

- Part 6. What are design rules in PCB layout?

- Part 7. How do I choose the right PCB material?

- Part 8. What is the difference between single-layer and multi-layer PCBs?

- Part 9. How do I reduce noise and interference in circuit board design?

- Part 10. What are common PCB design mistakes to avoid?

- Part 11. FAQs about Circuit Board Design

Part 1. What is circuit board design?

Circuit board design is the process of planning and creating the layout of a printed circuit board (PCB) that connects electronic components using conductive tracks, pads, and vias. It involves schematic creation, component placement, routing, and preparing files for manufacturing.

Part 2. How do I start designing a circuit board?

To start, define your circuit’s function and create a schematic diagram using design software. Then, select components, assign footprints, and arrange them on the PCB layout. After routing the traces, check design rules, and generate manufacturing files like Gerbers for production.

Part 3. What software is best for PCB design?

Popular PCB design software includes Altium Designer, KiCad, Eagle, OrCAD, and EasyEDA. Each offers schematic capture, layout design, and simulation tools. KiCad and EasyEDA are free options, while Altium and OrCAD are preferred for professional, high-complexity projects.

Part 4. What are the basic steps in circuit board design?

The main steps are:

- Define the circuit’s requirements.

- Create a schematic diagram.

- Assign footprints to components.

- Design the PCB layout and route traces.

- Perform design rule checks (DRC).

- Generate Gerber and drill files for manufacturing.

Part 5. How do I create a schematic for a PCB?

Use schematic design software to draw the electrical connections between components using symbols. Assign part numbers and values, verify connections, and ensure signal flow. Once complete, the schematic is used to generate a netlist for the PCB layout stage.

Part 6. What are design rules in PCB layout?

Design rules define constraints like trace width, spacing, via size, and clearance between elements to ensure reliability and manufacturability. They prevent shorts, signal loss, and mechanical issues. Rules depend on board type, voltage levels, and manufacturer capabilities.

Part 7. How do I choose the right PCB material?

Select materials based on signal speed, thermal performance, and cost. FR4 (fiberglass epoxy) is most common, offering good balance for general use. High-frequency designs may use Rogers or polyimide materials for better dielectric and heat resistance.

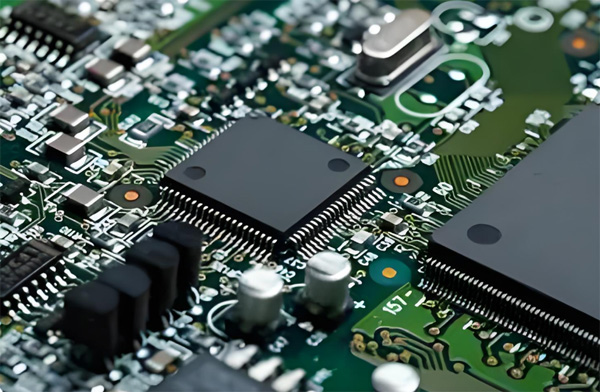

Part 8. What is the difference between single-layer and multi-layer PCBs?

Single-layer PCBs have one conductive layer, ideal for simple circuits. Multi-layer PCBs contain multiple copper layers separated by insulation, enabling complex routing, better signal integrity, and reduced EMI—used in advanced electronics like computers and smartphones.

Part 9. How do I reduce noise and interference in circuit board design?

Minimize noise by separating analog and digital grounds, using short signal paths, adding decoupling capacitors near ICs, and maintaining proper trace spacing. Shield sensitive components and use ground planes for stable reference and reduced electromagnetic interference (EMI).

Part 10. What are common PCB design mistakes to avoid?

Avoid poor component placement, overlapping traces, missing ground planes, or ignoring DRCs. Also, ensure correct trace width for current capacity, avoid sharp trace angles, double-check net connections, and verify polarity and orientation of polarized components before fabrication.

Part 11. FAQs about Circuit Board Design

How do I design for high-speed circuits?

Use controlled impedance traces, short signal paths, proper termination, and ground planes. Maintain consistent trace width and spacing to reduce reflections and crosstalk.

What are vias in PCB design and how are they used?

Vias are holes plated with copper that connect traces between layers. They help route signals, power, and ground between different PCB layers efficiently.

How do I manage power and ground planes in PCB layout?

Use solid, continuous planes for power and ground. Keep them close to each other to reduce noise and improve signal return paths and EMI shielding.

What are impedance control and why are they important in PCB design?

Impedance control ensures consistent signal transmission by matching trace impedance with circuit requirements, preventing reflections and signal loss in high-speed designs.

How do I design a PCB for manufacturing (DFM)?

Follow manufacturer guidelines for trace widths, spacing, drill sizes, and component placement. Ensure clear labeling, solder mask alignment, and proper tolerances.

What are the thermal management techniques in PCB design?

Use thermal vias, heat sinks, copper pours, and wider traces for high-current paths. Place heat-generating components apart to improve airflow and dissipation.

How do I ensure signal integrity in circuit board design?

Keep traces short, use proper impedance control, add ground planes, and avoid 90° angles. Separate analog and digital signals to minimize interference.

What are the best practices for PCB component placement?

Group components by function, place connectors at board edges, and keep sensitive parts away from heat sources or noisy circuits. Optimize for routing and testing.

How do I perform a design rule check (DRC)?

Run the DRC tool in your PCB software to detect spacing, clearance, and trace width errors. Fix all violations before generating manufacturing files.

How do I prepare Gerber files for PCB fabrication?

Export Gerber and drill files from your design software, including all layers (copper, solder mask, silkscreen). Verify them using a Gerber viewer before sending to the manufacturer.

A professional with over a decade of experience in the PCB depaneling industry.