Punching depaneling is a fast, low-cost method for separating PCBs in high-volume production. In this guide, I’ll walk you through how it works, its advantages, and when it’s the right choice.

- Part 1. What is punching depaneling in PCB manufacturing?

- Part 2. How does a PCB punching machine work?

- Part 3. What are the advantages of punching depaneling over routing?

- Part 4. What types of PCB designs are suitable for punching depaneling?

- Part 5. What are the limitations of punching depaneling?

- Part 6. How accurate is punching depaneling compared to laser depaneling?

- Part 7. What is the typical tolerance of punched PCBs?

- Part 8. Can punching depaneling be used for flexible PCBs (FPC)?

- Part 9. How long does it take to design and manufacture a punching die?

- Part 10. What is the average lifespan of a punching tool or die?

- Part 11. FAQs about punching depaneling

Part 1. What is punching depaneling in PCB manufacturing?

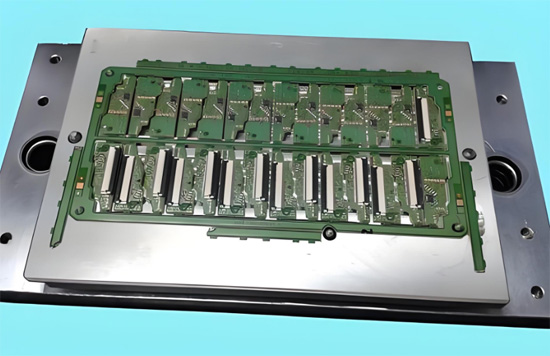

Punching depaneling is a method used to separate individual PCBs from a panel by applying force through a custom-made die set. The die is pressed down to cut along predefined outlines, quickly and cleanly separating the boards. It’s ideal for high-volume production where speed and consistency are priorities.

Part 2. How does a PCB punching machine work?

A PCB punching machine uses a hydraulic or pneumatic press along with a specially designed metal die. The panel is placed between the die and a support base. When pressure is applied, the die punches out the individual PCBs along the scored or routed outlines in a single or multiple strokes.

Part 3. What are the advantages of punching depaneling over routing?

Punching is much faster and more consistent for large batches. It doesn’t produce dust, reduces mechanical stress, and requires less labor. Once the die is made, the per-board cost is low, making it ideal for mass production of PCBs with simple or repeated layouts.

Part 4. What types of PCB designs are suitable for punching depaneling?

Punching works best for rigid PCBs with simple, repetitive shapes and well-defined outlines. Designs should avoid tight curves or irregular profiles. It’s commonly used for consumer electronics, toys, and LED boards with rectangular or circular patterns.

Part 5. What are the limitations of punching depaneling?

Punching requires a custom die, which can be expensive and time-consuming to make. It’s not suitable for low-volume production or complex board shapes. It also lacks flexibility—any design change means a new die is needed. High force may damage delicate components if not properly supported.

Part 6. How accurate is punching depaneling compared to laser depaneling?

Punching is less precise than laser depaneling. Tolerances typically range from ±0.1 mm to ±0.2 mm, depending on die quality and material stability. While laser offers high-precision cuts with complex shapes, punching provides speed and economy but with limited design flexibility.

Part 7. What is the typical tolerance of punched PCBs?

Typical dimensional tolerance for punched PCBs ranges from ±0.1 mm to ±0.2 mm. This level of accuracy is generally acceptable for many commercial and industrial applications, especially when the design doesn’t require intricate features or extremely tight fits.

Part 8. Can punching depaneling be used for flexible PCBs (FPC)?

Punching can be used for flexible PCBs, but it requires careful die design to prevent tearing or distortion. The softer material of FPCs needs precise support during punching, and tolerance control can be more challenging than with rigid boards.

Part 9. How long does it take to design and manufacture a punching die?

It typically takes 1 to 3 weeks to design and fabricate a punching die, depending on the complexity of the PCB shape and the die manufacturing queue. The process includes designing, machining, testing, and adjusting to ensure perfect alignment with the board layout.

Part 10. What is the average lifespan of a punching tool or die?

A well-maintained punching die can last for 100,000 to over 1,000,000 strokes, depending on the material, PCB thickness, and cutting edge quality. Regular maintenance like sharpening and cleaning extends its lifespan and ensures consistent performance.

Part 11. FAQs about punching depaneling

Is punching depaneling suitable for high-volume PCB production?

Yes, it’s ideal for high-volume production due to its speed, repeatability, and low per-unit cost after tooling.

What materials are used for punching tools in PCB depaneling?

Punching tools are typically made from hardened tool steel or tungsten carbide for durability and precision.

How does punching affect PCB edge quality?

Punching produces clean, straight edges but may leave slight burrs or stress marks if the die is worn or misaligned.

Can punching depaneling damage components near the board edge?

Yes, if components are placed too close to the punch line, mechanical force may stress or crack them.

What maintenance is required for a PCB punching machine?

Regular maintenance includes die sharpening, lubrication, alignment checks, and inspection for wear or damage.

How much does a PCB punching machine cost?

Prices range from $5,000 to $50,000 depending on automation level, size, and features. Custom dies are extra.

What’s the difference between single-punch and compound die punching?

Single-punch performs one cut at a time; compound dies can make multiple cuts or forms in one press stroke.

How do you design a PCB panel for punching depaneling?

Ensure consistent shapes, proper spacing, and strong tooling holes. Avoid sharp angles or tight internal radii.

Is punching depaneling compatible with SMT (surface mount technology) assemblies?

Yes, but care must be taken to support the PCB during punching to avoid damaging SMT components.

What are common quality control checks after punching depaneling?

Checks include edge quality, dimensional accuracy, absence of cracks, burrs, or misalignment, and component integrity.

A professional with over a decade of experience in the PCB depaneling industry.