Want to learn more about V-Cut depaneling? This article answers all the common questions you might have. Let’s explore together!

- Part 1. What is V-Cut depaneling in PCB manufacturing?

- Part 2. How does a V-Cut PCB separator work?

- Part 3. What types of PCBs are suitable for V-Cut depaneling?

- Part 4. What are the advantages of V-Cut depaneling?

- Part 5. What are the limitations of using V-Cut for PCB separation?

- Part 6. How deep should the V-groove be in a PCB panel?

- Part 7. Can V-Cut depaneling damage components near the edge?

- Part 8. Is V-Cut suitable for flexible or irregular-shaped PCBs?

- Part 9. What’s the minimum distance between V-groove and PCB components?

- Part 10. How is V-Cut different from routing or laser depaneling?

- Part 11. FAQs about V-Cut depaneling

Part 1. What is V-Cut depaneling in PCB manufacturing?

V-Cut depaneling is a method used in PCB manufacturing to separate individual circuit boards from a larger panel. During production, V-shaped grooves are cut along the separation lines on both sides of the panel. These grooves create a weak point, allowing the boards to be snapped apart manually or by machine. It’s a fast, cost-effective method ideal for straight-line cuts on rigid PCBs. V-Cut is commonly used in high-volume production where board shapes are simple and edge-mounted components are properly spaced from the grooves.

Part 2. How does a V-Cut PCB separator work?

A V-Cut PCB separator works by aligning the V-grooved PCB panel between two circular blades—one above and one below. The lower blade stays fixed while the upper blade moves downward, guiding the board through the groove and applying pressure along the V-cut line. This controlled shearing action cleanly separates the boards without bending or stressing them. The machine ensures straight, even cuts and is ideal for high-volume, straight-line depaneling of rigid PCBs.

Part 3. What types of PCBs are suitable for V-Cut depaneling?

V-Cut depaneling is suitable for rigid PCBs with straight edges and simple rectangular or square shapes. It works best when the boards are laid out in a panel with V-shaped grooves cut along the separation lines. This method is ideal for high-volume production where speed and cost are important. However, it’s not recommended for flexible PCBs, curved outlines, or boards with components placed too close to the edge, as the stress during separation may cause damage.

Part 4. What are the advantages of V-Cut depaneling?

V-Cut depaneling offers several advantages. It is fast, simple, and cost-effective, making it ideal for high-volume PCB production. The process uses V-shaped grooves to allow easy separation with minimal equipment. It produces clean, straight edges and causes little to no dust. V-Cut machines are easy to operate and maintain. Because it’s a mechanical process, it doesn’t generate heat, reducing the risk of thermal damage to components. It’s best suited for boards with straight-line layouts.

Part 5. What are the limitations of using V-Cut for PCB separation?

V-Cut depaneling has some limitations. It only supports straight-line cuts, so it’s not suitable for curved or complex board shapes. It can’t be used for flexible PCBs, and placing components too close to the V-groove may lead to damage during separation due to mechanical stress. Also, it requires careful panel design with accurate V-groove placement. While it’s fast and low-cost, it lacks the precision and versatility of methods like laser or router depaneling.

Part 6. How deep should the V-groove be in a PCB panel?

The V-groove in a PCB panel is typically cut to about one-third to one-half of the total board thickness from both the top and bottom sides. This means the remaining material, or web thickness, in the center is usually around 0.3 mm to 0.5 mm. The depth must be enough to allow easy and clean separation without breaking the board prematurely. Proper groove depth ensures the PCB remains strong during handling but can still be snapped apart without damaging components.

Part 7. Can V-Cut depaneling damage components near the edge?

Yes, V-Cut depaneling can potentially damage components placed too close to the edge or the V-groove. During separation, mechanical stress is applied along the groove line, which may cause cracks, solder joint damage, or even break fragile parts near the edges. To prevent this, designers must keep a safe clearance between the V-groove and any components or copper traces. Proper panel layout and spacing help ensure components remain safe during the depaneling process.

Part 8. Is V-Cut suitable for flexible or irregular-shaped PCBs?

No, V-Cut depaneling is generally not suitable for flexible or irregular-shaped PCBs. It works best with rigid boards that have straight edges and simple shapes because the process relies on straight V-shaped grooves for easy snapping. Flexible PCBs can bend or deform during separation, causing damage. Irregular or curved shapes cannot be properly grooved with straight V-cuts, leading to uneven breaks or board damage. For these types of PCBs, other methods like laser or router depaneling are more appropriate.

Part 9. What’s the minimum distance between V-groove and PCB components?

The minimum distance between the V-groove and PCB components is generally recommended to be at least 1.5 to 2 millimeters. This clearance helps prevent mechanical stress during depaneling from damaging nearby components or solder joints. Keeping components too close to the groove increases the risk of cracking or breaking during the snapping process. Designers should also avoid placing sensitive parts, such as large chips or connectors, near the V-cut line to ensure safe and reliable board separation.

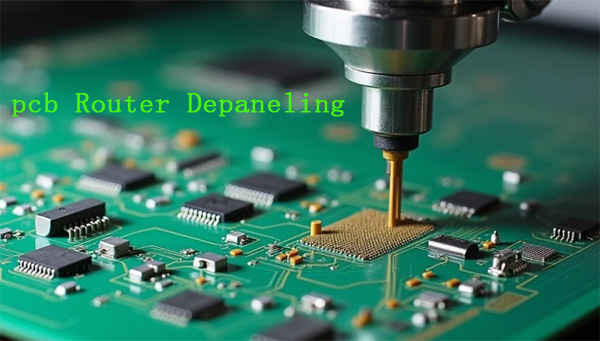

Part 10. How is V-Cut different from routing or laser depaneling?

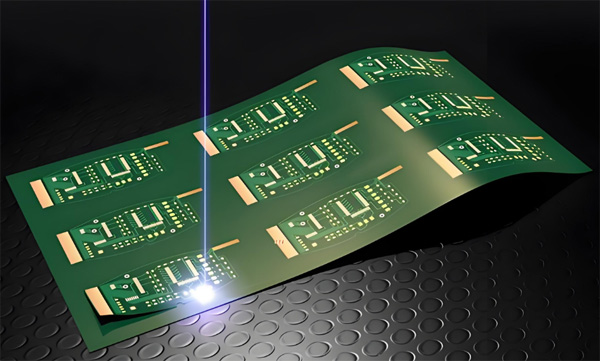

V-Cut depaneling uses pre-cut V-shaped grooves on both sides of a PCB panel, allowing boards to be snapped apart easily along straight lines. It is fast, low-cost, and produces minimal dust but only works for simple, straight cuts. Routing uses a spinning cutter to mechanically carve out complex shapes, offering more flexibility but generates dust and may stress the board. Laser depaneling uses focused light to cut with high precision and clean edges, suitable for complex shapes and delicate boards but involves higher costs and slower speeds.

Part 11. FAQs about V-Cut depaneling

What kind of machine is used for V-Cut depaneling?

A V-Cut depaneling machine with two circular blades (upper and lower) precisely shears PCB panels along the V-grooves.

Does V-Cut depaneling generate dust or debris?

No, it produces minimal dust since it uses mechanical shearing instead of cutting or grinding.

How precise is V-Cut compared to other methods?

V-Cut is precise for straight lines but less flexible than routing or laser methods for complex shapes.

Can V-Cut be automated in a production line?

Yes, V-Cut machines can be integrated into automated lines for efficient, fast depaneling.

What industries commonly use V-Cut depaneling?

Consumer electronics, automotive, lighting, and home appliances often use V-Cut for mass PCB production.

How does V-Cut affect PCB panel design?

Panels must have straight V-grooves with safe clearance from components to avoid damage during separation.

What is the typical blade life for a V-Cut machine?

Blade life varies but typically lasts thousands of panels before needing replacement, depending on usage.

How to avoid stress cracks when using V-Cut depaneling?

Maintain proper groove depth and keep components away from edges to reduce mechanical stress.

What safety precautions should be taken during V-Cut operation?

Use guards, avoid loose clothing, ensure proper training, and follow machine safety guidelines.

Is V-Cut depaneling suitable for high-volume production?

Yes, it is cost-effective and fast, making it ideal for high-volume, straight-line PCB depaneling.

A professional with over a decade of experience in the PCB depaneling industry.