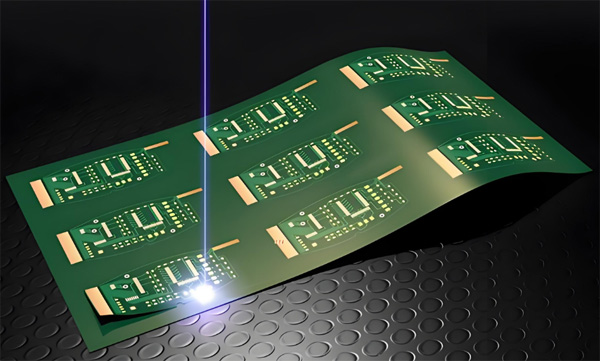

Making electronics requires cutting circuit boards (PCBs) from large panels. Laser depaneling is a modern method that uses light instead of blades or saws. It is very precise, gentle on delicate boards, and works with many materials. While it has some downsides—like high costs and heat effects—it’s a great choice for high-quality electronics. This method is especially useful for phones, medical devices, and cars.As a professional with more than ten years of experience in the PCB depaneling industry, I will explain the advantages, limitations and application industries of laser depaneling in this article.

What are the advantages of laser depaneling?

●High Accuracy

Laser depaneling cuts PCBs very precisely. It gives you clean, smooth edges without rough spots, which is great for small or detailed boards.

●No Physical Damage

Because the laser doesn’t touch the board, it won’t bend or crack it. This is safer for fragile parts and thin PCBs.

●Works with Many Materials

Lasers can cut many types of boards—hard, soft, thick, thin, or even flexible ones. It’s useful for many different projects.

●No Tool Wear

Lasers don’t wear out like blades or drills. You won’t need to stop work often to fix or replace parts.

●Saves Space

Laser cuts are very thin, so you can place PCBs closer together on the panel. This helps save space and materials.

●Clean Process

There’s no dust or mess when using a laser. This makes the workplace cleaner and safer.

●Easy to Automate

Laser machines can work with robots or other machines. Once set up, they cut the same way every time with little human help.

●Flexible Cutting Shapes

Lasers can cut any shape, not just straight lines. This is helpful for unique or small board designs.

What are the limitations of laser depaneling?

●High Equipment Cost

Laser depaneling machines are expensive to buy and set up. This can be a big investment, especially for small or medium-sized manufacturers.

●Slower for Certain Materials

Cutting thick or dense materials with a laser can be slower than using mechanical methods. This may reduce efficiency in high-volume production lines.

●Heat Effects on Materials

Laser cutting uses heat, which can slightly damage the edges of some materials. Extra care may be needed to avoid affecting nearby components.

●Needs Skilled Operation and Maintenance

Setting up and maintaining a laser system requires trained staff. Incorrect settings can lead to poor results or even damage to the board.

●Requires Fume Extraction and Safety Measures

Laser cutting can create fumes and tiny particles. Proper ventilation and safety systems are needed to protect workers and equipment.

What types of PCBs are suitable for laser depaneling?

●Rigid PCBs (FR4)

These are the most common solid boards used in electronics. Laser cutting works well for these, giving clean edges without cracks.

●Flexible PCBs (FPC)

These are thin and bendable boards. Lasers are perfect for cutting them because they don’t touch or damage the soft material.

●Rigid-Flex PCBs

These boards are part hard and part flexible. Laser depaneling can cut both parts smoothly, without harming the flexible sections.

●Ceramic PCBs

Ceramic boards are fragile and can easily crack with regular cutting. Lasers can cut them gently and accurately with no damage.

●Metal-Core PCBs (MCPCB)

These boards have a metal layer to help with heat. Special lasers can cut them too, though it may take a bit longer.

What industries commonly use laser depaneling?

●Electronics & Gadgets

Used in phones, tablets, and smartwatches. Laser cutting helps make tiny, detailed circuit boards without damage.

●Medical Devices

Used for small, delicate devices like hearing aids and health monitors. Lasers keep the boards safe and clean.

●Automotive

Used in car electronics like sensors and safety systems. Laser cutting makes strong, reliable boards for cars.

●Aerospace & Defense

Used in airplanes, satellites, and military gear. Lasers help make very accurate and reliable circuit boards.

●Industry & Robots

Used in factory machines and robots. Lasers cut boards quickly and cleanly for machines to work well.

Conclusion

I believe laser depaneling is a smart and precise way to cut circuit boards. Although the machines can be expensive, they help us produce higher-quality products with less material waste. As electronics continue to get smaller and more complex, this technology is becoming even more essential. By using laser depaneling, we’re able to build stronger, more reliable devices—faster and cleaner—compared to traditional methods.

A professional with over a decade of experience in the PCB depaneling industry.