Features

●Dual-Table Design for Continuous Processing

The dual worktable configuration reduces loading and unloading time, allowing the laser to remain continuously in the processing state and improving overall efficiency.

●Large Processing Area

Offers a spacious processing area of 350 mm × 520 mm, suitable for a wide range of PCB depaneling tasks.

●Adapted for SMT Industry Applications

Ideal for processes such as depaneling pre-placed PCBs and opening cover film windows in SMT production lines.

●Optional Camera Target Pre-Positioning System

Can be equipped with a camera-based target alignment system to reduce positioning time and increase productivity.

Optional

- UV laser 15w, 20w, 25w or Green laser 35w, 60w

- Laser Height Sensor

- Barcode reader and MES system integration

- Laser cam power detection

- upgrade to Inline

Look no further! The same machines used by world’s top 500companies

Send us a direct message now, justsend us a picture of your product andwe’ll be able to recommend the rightproduct for you right away.

Specifications

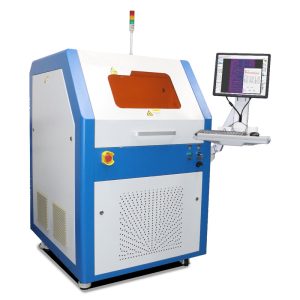

| Model | ZAM330 |

|---|---|

| Vaild cutting size | 350mm×520mm |

| Cutting function | Tweening to staight line,L shape,U shape,Circle,Arc |

| Process table | Two |

| Repeat precision | ±2μm |

| Cutting precision | ±20μm |

| Ambient Temperatur | 22℃±2℃(71.6℉±2℉) |

| Platform | Marble table |

| Transfer model(option) | Mechanical transfer arm(scrap board throwing) |

| Laser wavelength | 355nm/532nm |

| Receive Data Forma | Gerber, HPGL, Sieb & Meier, Excellon, ODB++ |

| Operation system | Windows 7 / Windows 10 |

| Target reads | CCD automatic target capture Target shape is irregular,

no Target, DIL is required Modules |

| Cutting software | DreamCreaTor |

| Data processing software | CircuitCAM 7 |

| XYZ-axis driving mode | linear +servo motor |

| Voltage/Power requirement | AC380V 50/60Hz 2.5KW three phase |

| Pneumatic pressure requirement | 0.6MPa,50L/min |

| Dimensions(W*D*H) | 1600mm x2100mm x1600mm |

| Weight | 2000KG |